Zinc Die Casting

Welcome to MORELUX — Your Trusted Partner for Custom Zinc Die Casting Solutions

Zinc die casting stands out for its ability to produce complex, high-precision parts quickly and economically. The low melting point of zinc reduces energy consumption and tooling wear, while its excellent fluidity allows for thin walls and intricate designs. This results in parts that are strong, lightweight, and dimensionally stable, with a superior finish that often requires minimal post-processing.

With over 20 years of manufacturing expertise, MORELUX specializes in delivering high-quality, precision-engineered custom zinc die casting parts tailored to your exact specifications. As a leading Chinese die casting factory, we combine advanced technology, skilled craftsmanship, and industry knowledge to provide durable, cost-effective, and intricately detailed zinc components for a wide range of industries.

Whether you need a prototype or high-volume production, MORELUX is your reliable partner for custom zinc die casting. Our experienced team will guide you from design to delivery, ensuring your parts meet the highest standards of quality and performance. Contact us now for a free consultation and quote.

Zinc Die Casting Material Properties and Advantages

- Mechanical Strength and Durability: Zinc alloys offer superior strength, hardness, and toughness versus aluminum and magnesium, with excellent tensile strength, impact, and wear resistance, extending part life.

- Dimensional Accuracy and Stability: Zinc die casting achieves high accuracy and stability, allowing net shape parts with ±0.001” repeatability.

- Corrosion Resistance: Zinc forms a protective oxide layer, making it highly corrosion-resistant for outdoor and harsh environments.

- Thermal and Electrical Conductivity: Zinc’s excellent conductivity aids heat dissipation and electrical applications.

- Low Melting Point: Melting at 419.5°C, zinc reduces energy use, die wear, and speeds casting compared to aluminum and magnesium.

- High Fluidity: Zinc’s fluidity fills intricate molds with thin walls, enabling complex, precise parts with minimal material.

- Recyclability: Zinc is fully recyclable, promoting sustainable manufacturing.

MORELUX: Zinc Die Casting Manufacturer

A Trusted Partner in Zinc Die Casting with over 20 Years Experience

MORELUX is more than just a parts manufacturer—we collaborate with you to develop effective solutions. With a heritage of quality and a commitment to innovation, we support businesses in achieving success. From initial concept through final production, our team partners closely with you to provide zinc die castings that not only meet but surpass your expectations.

Flash-Free Process

Removes surplus material, reducing both time and expenses.

Precision Expertise

We easily handle tight tolerances and intricate designs.

Energy Efficiency

Our streamlined manufacturing methods lower environmental impact and costs.

On-Time Delivery

We guarantee your parts arrive exactly when needed, ensuring seamless production flow.

Zinc Die Cast Material

to Meet Your Needs

From MORELUX’s perspective, we offer a comprehensive range of Zinc Die Cast Materials tailored to meet diverse customer needs.

- Zamak 2: High strength and good corrosion resistance.

- Zamak 3: Most popular alloy with excellent casting properties.

- Zamak 5: Enhanced strength and wear resistance.

- Zamak 7: Superior mechanical properties and toughness.

- Zamak 8: Improved ductility and impact resistance.

- ACuZinc5: Copper-enhanced for better strength and hardness.

- EZAC: Special alloy for excellent casting and finishing.

- ZA 27: High strength with good thermal conductivity.

- BERIC: Balanced alloy for durability and precision.

- ZP2: Good corrosion resistance and dimensional stability.

- ZP3: Improved mechanical strength and surface finish.

A Variety of Surface Finishes

for Precision Zinc Die Casting

At MORELUX, we specialize in precision zinc die casting with a wide range of surface finishes. We ensure each finish is precise and durable. We help customers achieve the perfect look and function for their zinc die cast parts.

- Polishing: Produces a shiny, reflective, mirror-like surface, often used when a high-gloss aesthetic is desired.

- Shot Blasting or Bead Blasting: Creates a uniform matte or textured surface, improving appearance and preparing the part for further coatings.

- Electroplating (e.g., Chrome, Nickel, Zinc plating): Adds a metal layer that enhances corrosion resistance, wear resistance, and electrical conductivity.

- Powder Coating and Painting: Provides color, additional corrosion protection, and a durable finish. Powder coating yields a harder finish than conventional paint.

- Conversion Coatings (Alodine, NCP): Chemical treatments that passivate the surface, improve corrosion resistance, and serve as primers for paint or plating.

Zinc Die Casting Process at Morelux

Morelux Zinc Die Casting process combines advanced mold manufacturing, precise high-pressure injection, rapid cooling, and thorough finishing to produce high-quality zinc alloy parts. The process is efficient, cost-effective, and capable of producing complex shapes with excellent mechanical properties. Morelux’s commitment to quality and innovation ensures their zinc die castings meet the demanding needs of industries such as lighting and machinery.

Step1: Design and Mold Preparation

The process begins with designing the component using detailed CAD models. This step ensures the final product meets exact specifications and functional requirements. After design approval, MORELUX fabricates a high-precision steel mold (die), consisting of two halves: the fixed die and the cover die. The mold is engineered to withstand high pressure and repeated use, ensuring durability and accuracy throughout production.

Step2: Melting the Zinc Alloy

Zinc alloys used by MORELUX typically contain small amounts of aluminum, copper, and other metals to enhance strength and corrosion resistance. Zinc’s low melting point (around 420°C) is a major advantage, allowing energy-efficient melting and reducing thermal stress on the mold. This low melting temperature also enables faster cycle times and extends mold life compared to other metals like aluminum or magnesium.

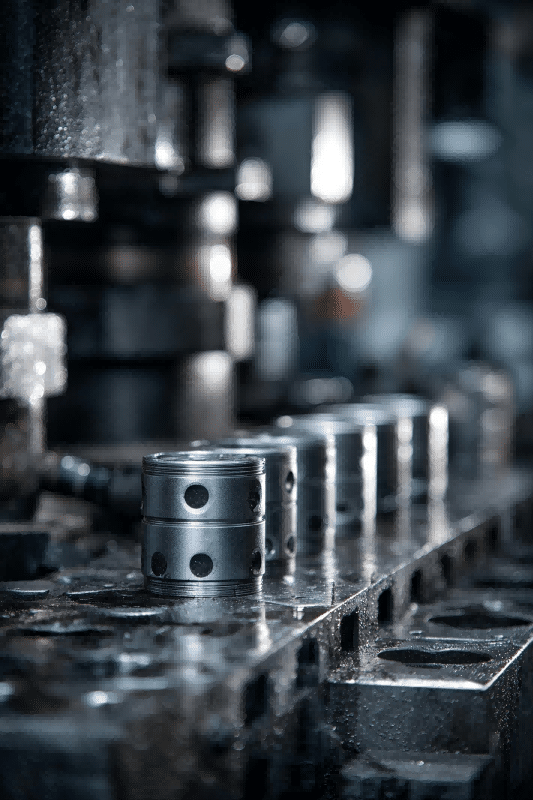

Step3: Injection of Molten Zinc

The molten zinc alloy is held at the optimal temperature in a holding pot. Using a hot chamber die casting machine, the molten metal is injected under high hydraulic pressure into the mold cavity through a gooseneck system. The pressure ensures the molten zinc fills every intricate detail of the mold, creating parts with excellent dimensional accuracy and surface finish. Injection and filling happen extremely fast, typically within 10 to 20 milliseconds.

Step4: Cooling and Solidification

Once injected, the molten zinc cools and solidifies quickly inside the steel mold due to zinc’s high thermal conductivity. This rapid chill produces a fine-grained microstructure, which enhances mechanical properties such as strength and toughness. Cooling time varies depending on part thickness but is generally short, enabling high-volume production with cycle rates of more than 2,000 parts per hour for small parts.

Step5: Ejection and Trimming

After solidification, the mold halves open, and the solid zinc casting is ejected. Typically, the cast part will have some excess material or flash around its edges. MORELUX expertly removes this unwanted material through precise trimming and finishing operations. Additional finishing steps may include CNC machining, grinding, polishing, or powder coating to meet stringent quality and aesthetic standards.

Zinc Die Casting Applications

At MORELUX, we leverage zinc’s excellent metal properties to deliver superior zinc die casting solutions. Our expertise meets diverse industry needs with high-durability, high-efficiency and high-tolerance. If you need a more detailed technical datasheet or case studies for any specific application, feel free to ask!

Aerospace zinc alloy die casting

In aerospace, zinc strength-to-weight ratio and stability under stress are critical. MORELUX supplies zinc die cast parts for aircraft interiors, control panels, and structural components. Our precision casting meets strict aerospace standards, ensuring safety and performance in demanding environments.

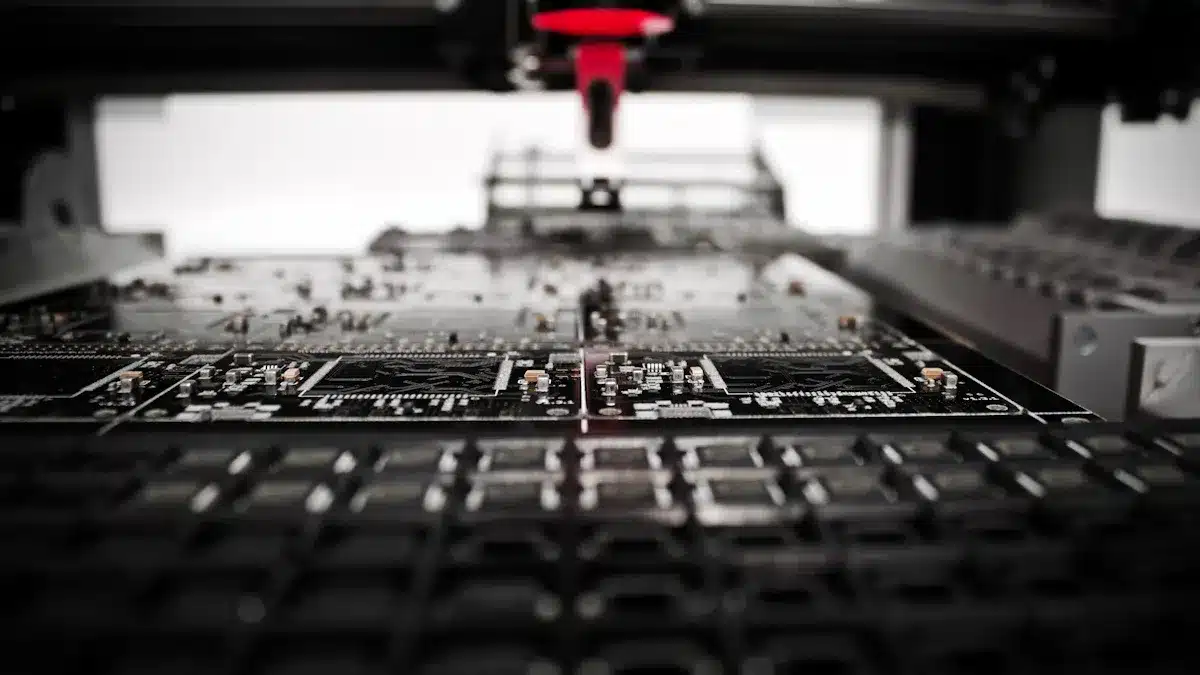

Electronic zinc alloy die casting

Zinc excellent electrical conductivity and shielding properties make it ideal for electronic housings and connectors. MORELUX produces zinc die cast parts that protect sensitive electronics from electromagnetic interference. Our fast, precise casting supports high-volume manufacturing with consistent quality.

Medical zinc alloy die casting

MORELUX serves the medical industry by producing zinc die cast components that require biocompatibility and corrosion resistance. Our parts are used in medical devices, diagnostic equipment, and surgical instruments. Zinc antimicrobial properties add an extra layer of safety and hygiene.

Miniature parts zinc die casting

Zinc fluidity and low melting point allow MORELUX to produce intricate miniature parts with fine details. These parts are lightweight yet strong, ideal for precision instruments, small mechanical components, and decorative items. Our process ensures consistent quality and tight tolerances for reliable performance.

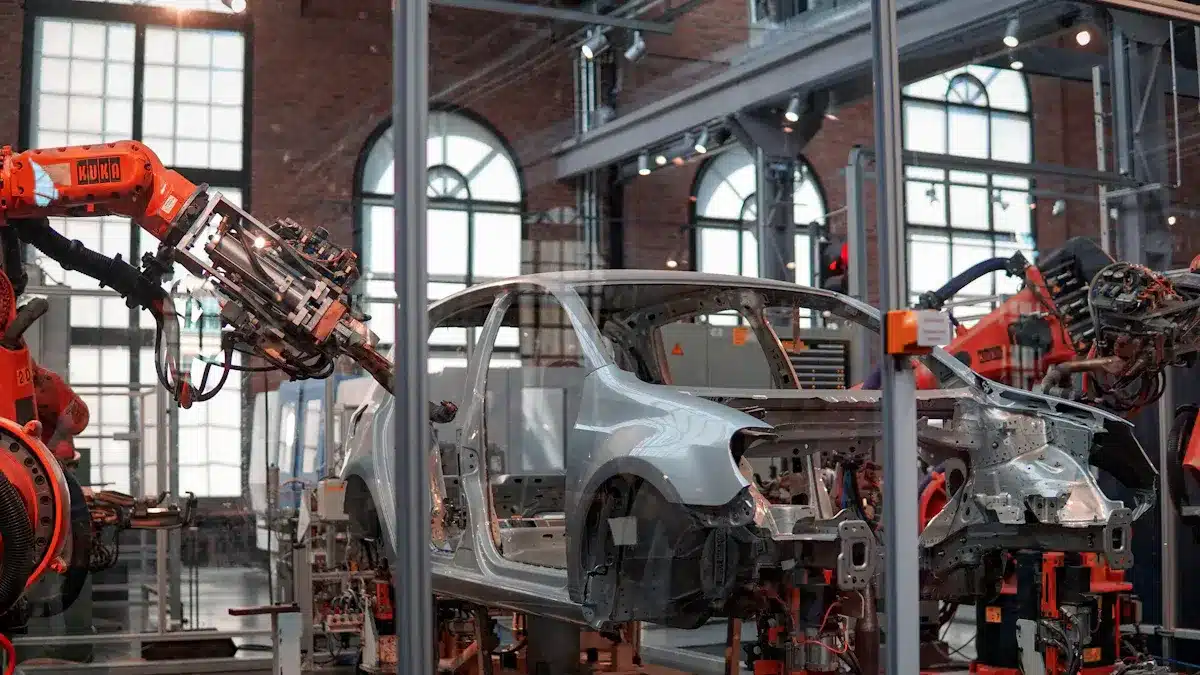

Automotive parts zinc die casting

MORELUX provides zinc die casting for automotive components requiring strength and corrosion resistance. Zinc alloys offer excellent wear resistance and dimensional accuracy, perfect for gear housings, brackets, and connectors. Our parts improve vehicle durability while reducing weight and manufacturing costs.

More custom zinc die casting

Beyond standard applications, MORELUX offers custom zinc die casting tailored to unique client needs. We work closely with customers to optimize design, material selection, and production processes. Our flexible approach supports rapid prototyping and large-scale manufacturing across various industries.

FAQS about Zinc Die Casting

How strong are zinc die casts?

Zinc die castings are known for their high strength, durability, and excellent precision. Zinc alloys like Zamak 3 offer good creep resistance and allow for thin-wall casting, making them ideal for complex and detailed parts. They also have a low melting point, which helps in fast production cycles and long tool life. Zinc die cast parts are tough, corrosion-resistant, and provide a superior finish. However, they cannot be welded due to heat sensitivity.

For reliable and high-quality zinc die castings, MORELUX is a great choice. With over 20 years of experience, MORELUX offers precision die casting, mold design, CNC machining, and finishing services. We serve industrial sectors with excellent customer support and cost-effective solutions. Our expertise ensures durable and well-finished zinc components tailored to your needs.

Will Zinc Die Cast Rust?

Zinc die castings do not rust like iron or steel because zinc contains little iron and forms a protective zinc oxide layer when exposed to air. This layer prevents the metal from red rust, which is typical for iron-based metals. Zinc alloys can corrode over time, but this results in harmless white rust that does not affect the part’s strength. Zinc die castings are highly corrosion resistant, durable, and suitable for many environments except very severe marine conditions.

For reliable zinc die cast parts, MORELUX offers high-quality zinc die castings known for strength, corrosion resistance, and smooth finishes. They provide excellent options for both functional and decorative applications with good durability and aesthetic appeal.

How to brighten die cast zinc?

For high-quality zinc die castings and finishing services, MORELUX offers a range of options to meet various aesthetic and functional requirements. To brighten die-cast zinc, you can use several methods:

- Cleaning Solution: A cleaning solution made of phosphoric acid, butyl alcohol, water, and a wetting agent can brighten tarnished die castings. Immerse degreased castings for 10-20 seconds, then rinse and dry them.

- Vibratory Finishing: Vibratory processes use abrasive media in a rotating drum to smooth and brighten surfaces, remove burrs, and eliminate loose debris.

- Polishing: This classic technique creates a shiny, reflective surface, ideal for a high-gloss finish.

- Plating: Applying a thin layer of metal like chrome, nickel, or copper-nickel-chrome can enhance appearance and improve corrosion resistance.

- Thermal Deburring: This process can smooth and brighten surfaces while removing flashes and rounding sharp edges.

Zinc Die Cast vs. Aluminum vs. Stainless Steel

- Zinc Die Cast: Stronger and denser than aluminum, with excellent impact resistance and tight dimensional tolerances. It offers fast production cycles, good corrosion resistance, and smooth surface finishes. Zinc is cost-effective due to lower melting temperatures and longer die life. Ideal for intricate, small to medium parts with high precision.

- Aluminum Cast: Much lighter than zinc, with a superior strength-to-weight ratio. It has excellent heat resistance and corrosion resistance, making it suitable for automotive and electronics parts. Aluminum parts may require more finishing and have slower production cycles. Better for larger, structural components where weight matters.

- Stainless Steel Cast: Stronger and more corrosion-resistant than zinc but much heavier and more expensive. Production costs are higher, and die life is shorter compared to zinc. Stainless steel is chosen for durability and extreme environment applications but less common for die casting due to cost.

For high-quality, cost-effective die casting services, MORELUX provides expert zinc, aluminum, and stainless steel die casting solutions. We ensure precision, fast turnaround, and excellent surface finish, meeting diverse industry needs with competitive pricing and professional support.