PRECISION DIE-CASTING

FROM MALAYSIA

We turn your engineering and design innovations into tangible, high-quality parts and components that function optimally and meet your highest expectations.

WHO WE ARE

Your Trusted Precision

Die-casting Manufacturer

MORELUX is a leading professional manufacturer specializing in precision die casting, dedicated to delivering high-quality metal components for industries such as automotive, electronics, telecommunications, and industrial equipment. With advanced production technology, strict quality control, and a customer-centric approach, MORELUX provides customized die-casting solutions that meet global standards. Our expertise covers aluminum, zinc, and magnesium alloy die casting, along with precision machining and surface treatment services. Committed to innovation and excellence, MORELUX ensures durability, precision, and cost-efficiency in every product. Partner with us for reliable, high-performance die-casting solutions tailored to your needs.

MORELUX Provide One Stop Die-Casting Solution

Metal for Die-Casting

Provide by MORELUX

MORELUX provides an extensive range of premium metals specifically designed for die casting applications. Our diverse selection ensures that you can find the perfect material to suit the unique requirements of your project. By choosing MORELUX metals, you guarantee superior quality and optimal performance in every manufacturing process.

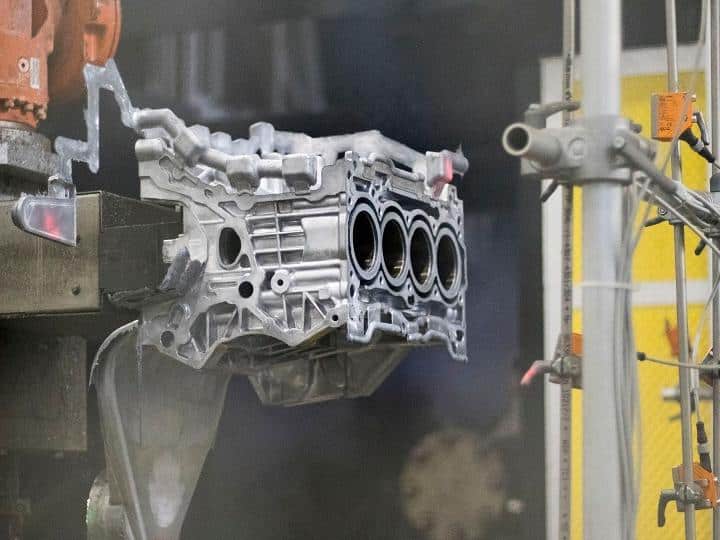

Aluminum Die-Casting

Aluminum die castings are lightweight, strong, corrosion-resistant, and excel in high-temperature durability.

Zinc Die-Casting

Zinc die casting rapidly creates complex, durable parts with excellent surface finish, using less energy than other methods.

Copper Die-Casting

Copper is durable, highly conductive, fully recyclable, ideal for electrical and thermal uses without losing strength.

DIVERSE INDUSTRIES

Die-Casting Industries Served

MORELUX Quality Control for Die Cast Parts

- MORELUX focuses strongly on quality, ensuring consistency and reliability.

- Quality control starts early in part and process design phases.

- Skilled engineers work closely with customers and suppliers throughout development.

- Advanced technologies are used for inspection, including X-ray and CMM machines.

- An Optical Emission Spectrometer checks material composition precisely.

- Leak tests are performed to meet required specifications.

- Ensures all die cast parts meet the highest quality standards.

Latest Die-Casting Blogs by MORELUX

How Die Casting Technology Powers the Leap Forward in Electric Drive Systems

As electric vehicles (EVs) rapidly surge in popularity, the electric drive system (e-drive) stands out as the heart of these new-energy vehicles. Its efficiency, weight,

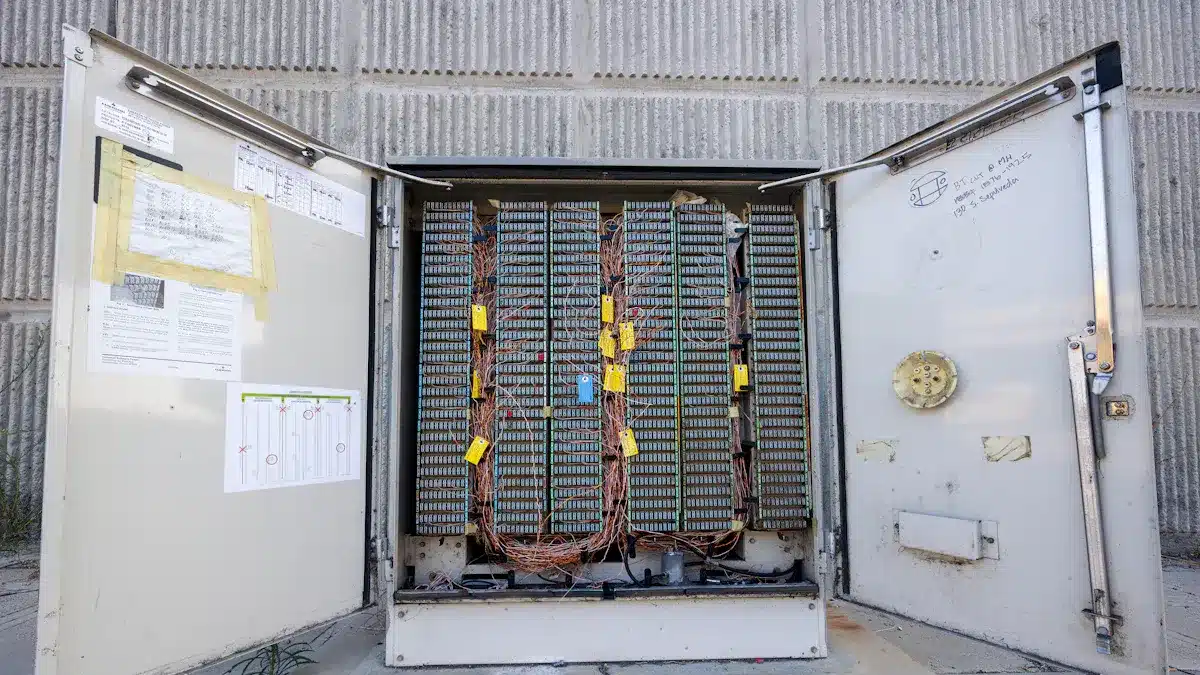

Die casting telecommunication housing boosts signal and safety

Telecom die-castings housing helps telecom equipment work better and stay safe. Telecom workers use these housings to stop electromagnetic interference. This keeps signals clear and

Cutting-Edge Aluminum Die Casting Solutions for the Telecom Industry

Aluminum die-casting is transforming the way telecommunication infrastructure is built. It delivers precise, durable, and efficient solutions for modern networks. Reports indicate a rising demand