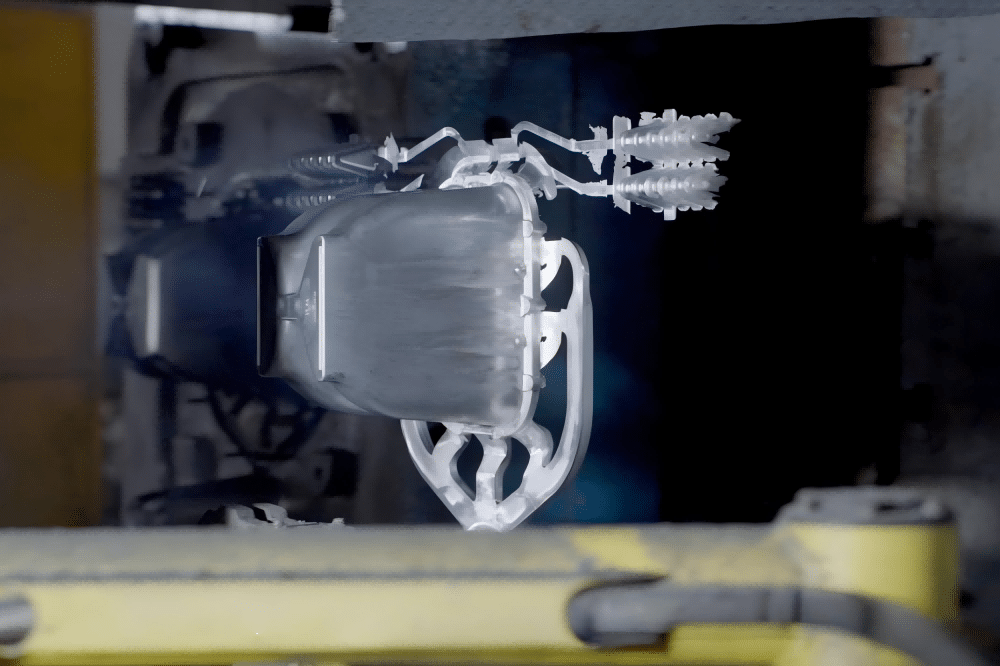

Die casting helps create many important die cast parts for everyday items and specialized machines. Companies utilize die casting aluminium and other metals to produce components that require high precision and intricate shapes. High pressure die casting, or HPDC, excels at manufacturing strong, lightweight, and complex parts quickly. Companies like MORELUX employ automated die casting machines to achieve outstanding results. Some common die cast parts include:

Engine blocks and transmission housings for cars

Lightweight parts and housings in airplanes

Enclosures, heat sinks, and connectors for electronics

Precision housings and brackets in medical devices

Pump housings and valves for industrial use

Die casting remains a primary method for producing robust and precise parts across various industries.

Key Takeaways

Die casting makes strong and light parts for many industries like cars, planes, and electronics.

High pressure die casting helps create exact and tricky shapes. This makes it good for parts with lots of details.

Aluminum and magnesium alloys are used a lot in die casting. They are strong and light.

Die casting helps factories work faster. It lowers costs and waste. It also makes sure parts are good quality.

The process helps people make new designs. It lets them create special shapes and features for each industry.

Die Cast Parts in Automotive

Car makers use die casting to make many important parts. This process helps build strong, light, and detailed pieces for cars. High pressure die casting, called HPDC, lets companies make parts that fit very well and look smooth. This way, cars can be safer and work better.

Engine Components

Car engines need parts that can handle heat and pressure. Die casting parts are important for building engines. Companies use metal die casting to make parts that are both strong and light. The most common engine die cast parts are:

Engine blocks

Intake manifolds

Cylinder heads

Aluminum die casting is used a lot for these parts because it is strong and not heavy. Magnesium die casting is also used when making parts even lighter is needed. The die casting mold shapes each part very carefully, so it fits just right in the engine.

Transmission Cases

Transmission cases keep the gears and moving parts safe inside a car’s transmission. Die casting makes these cases tough and exact. Aluminum die casting and magnesium die casting are both used to make them. Die casting lets companies make cases with thin walls and tricky shapes that are hard to do with other ways.

Transmission cases made with die casting have many good points over old ways:

Advantage | Description |

|---|---|

Lightweight Components | Aluminum die-casting makes light parts, which helps cars use less fuel. |

Greater Automation and Adaptability | New die casting machines work faster and better with more robots. |

Short Manufacturing Cycle | Fast production saves money and lets more parts get made. |

Increased Productivity | Fewer workers are needed for each part, so it costs less to make many. |

Increased Component Strength | Die casting makes strong parts that last longer in cars. |

Precision Parts Manufacturing | Die casting makes parts that fit very well and have special shapes. |

Design Freedom | Die casting lets companies make shapes that are hard to make with other ways. |

Improved Sustainability | Die casting uses most of the metal, so there is less waste. |

Die casting tools and new machines help companies make lots of transmission cases fast. Zinc die casting is sometimes used for small transmission parts that need to be very exact.

Structural Parts

Parts that hold up the car must be strong and light. Die casting makes wheels, brackets, and trim, which are more than 70% of car castings. These parts use aluminum and magnesium alloys to make cars lighter and save fuel. Car makers also use die casting for battery boxes, motor covers, and other tricky shapes in electric cars.

Aluminum die castings are strong but not heavy. This is good for safety and how well the car works. Magnesium die casting makes parts even lighter, which helps cars pollute less and use less gas. Metal die casting lets companies make detailed parts that stay strong under pressure.

Note: Die casting parts for cars must pass tough quality checks. Companies use special tools and tests to make sure every part is good.

Die casting helps make many car parts, from engine blocks to trim. This process helps car makers reach their goals for safety, saving fuel, and making new things.

Die Casting in Aerospace and Defense

Die casting is very important in aerospace and defense. Engineers use die casting parts because they are strong and light. These parts can also handle hard conditions. The die casting process uses high pressure to shape metals. Metals like aluminum, magnesium, and zinc are used. Metal die casting makes parts that help planes and military gear work safely.

Aircraft Components

Airplanes need parts that are strong but not heavy. Die casting makes engine housings, landing gear, and fuselage frames. These parts help lower weight and keep planes safe. Aluminum die casting parts do not rust and work in high heat. Magnesium die casting makes even lighter parts for wings and frames. The die casting mold shapes each part with detail. This helps every piece fit just right.

Aircraft designers pick die casting for these reasons:

Some die casting parts in planes are:

Engine housings for turbofan engines

Landing gear parts

Avionics housings

Fuselage frames

Body parts for the plane

Aluminum and magnesium die casting help planes fly farther and safer.

Avionics Housings

Avionics systems control many things in planes. Die casting makes housings that protect these electronics. The process lets companies make tricky shapes and tight fits. Metal die casting makes light and strong covers. These covers keep electronics safe from heat and shaking.

Avionics housings made by die casting give:

Exact sizes and tricky shapes

Safety for important systems

Help with heat control

Good quality every time

Zinc die casting is used for small connectors and parts. These parts need to be very exact. Die casting parts in avionics help planes work well.

Military Equipment

Military gear must be strong and work well. Die casting parts give the needed strength and accuracy. Metal die casting makes gun parts and ammo shells that work under stress. The process makes sure each part meets tough rules.

Military Equipment Type | Description |

|---|---|

Gun Parts | Parts used in guns |

Ammunition Shells | Cases for different types of ammo |

Die casting parts in defense include housings, brackets, and connectors. Engineers use die casting to make gear that lasts in tough places.

Die casting helps aerospace and defense by making strong and light parts. The process helps build safer planes and good military gear.

Die Cast Parts for Electronics

Electronics need die casting to make many important parts. The die casting process shapes metal into exact forms. These parts protect and support electronic devices. Companies use die casting parts to build strong products for homes, offices, and factories. Metal die casting helps make enclosures, heat sinks, and connectors. These parts help electronics work safely.

Enclosures and Housings

Enclosures and housings keep the inside parts safe. Die casting makes these covers strong and accurate. Designers use die casting molds to make shapes that fit tightly. Aluminum and zinc die casting help make enclosures that resist damage. These parts also look smooth. Die casting parts shield electronics from dust, water, and bumps.

Manufacturers pick die casting for enclosures for many reasons. The process makes thin walls and detailed shapes. This helps companies make lighter products that stay tough. Metal die casting gives a clean finish, so devices look good and feel solid. Die casting parts for enclosures are used in computers, routers, and control panels.

Tip: Die casting parts for housings can have vents, mounting holes, and snap fits. These features help devices work better and last longer.

Heat Sinks

Heat sinks help electronics stay cool. Die casting makes heat sinks that move heat away from chips. The process shapes metal into fins and channels that spread heat fast. Aluminum die casting is popular for heat sinks. It is light and moves heat well. Die casting parts for heat sinks are found in many devices that need cooling.

Many industries use die casting heat sinks to control heat. The table below shows how different devices benefit from die casting parts:

Device Type | Application Description | Benefits |

|---|---|---|

Big Data Servers | High efficiency die cast heatsinks used to manage heat output effectively. | Reduced temperatures by 15°C. |

Photovoltaic Inverters | Custom die casting heatsinks designed to fit solar power inverters. | Cut thermal resistance by 20%. |

Wind Power Systems | Die cast heatsinks used to enhance cooling in wind turbines. | Improved efficiency by 10%. |

Die casting parts for heat sinks help electronics last longer and stay safe. Metal die casting lets companies make tricky shapes that cool better. The die casting mold forms each fin and channel with care.

Connectors

Connectors join wires and circuits inside devices. Die casting makes connectors that are strong and exact. The process shapes metal into small, detailed parts with tight fits. Aluminum, magnesium, and zinc die casting help make connectors for many uses.

Die casting parts for connectors have many good points:

High accuracy and stable sizes, so parts are always right.

Can make tricky shapes and thin walls with tight fits.

Strong and tough parts with good mechanical strength.

Smooth finish that needs little extra work.

Can add holes and spaces for wires and connections.

Makes lots of parts fast and keeps costs low.

Even density, which helps with electricity and heat.

Can use different alloys like aluminum, magnesium, and zinc.

Fast, automated process saves time and boosts production.

Die casting parts for connectors are used in phones, computers, and machines. Metal die casting helps companies make connectors that last and work well. The die casting process makes sure each connector fits and works every time.

Note: Zinc die casting is often used for connectors that need more detail and strength. The die casting mold shapes each connector to meet exact rules.

Die casting helps the electronics industry by making reliable and precise parts. Companies use die casting parts to build devices people use every day.

Medical and Industrial Die Casting

Medical and industrial companies need die casting for exact parts. The die casting process makes parts that meet tough safety rules. Companies use die casting to make smooth and accurate shapes. These industries want parts with no mistakes, so every die must work well. Extra steps like CNC machining and coating make each part stronger and look better.

Medical Device Housings

Medical device housings keep equipment safe. Die casting makes housings for many devices, such as:

Medical electronic equipment

Surgical devices

Therapy and diagnostics

Dental equipment

Ophthalmic devices

Laboratory equipment

Pharmaceutical equipment

Respiratory equipment

Robotic systems

Die casting gives the high accuracy these products need. The die shapes each housing with tight tolerances, like ±0.05 mm for most features and ±0.02 mm for important fits. Aluminum die casting is used a lot because it makes housings light and strong. Magnesium die casting is used for even lighter devices. The die casting mold helps make tricky shapes and smooth surfaces, which are good for safety and cleaning.

Component Type | Application Examples | Key Requirements |

|---|---|---|

Device Housings | Portable monitors, infusion pumps, ventilators | Lightweight, impact resistance, finish compatibility |

Electronic Enclosures | ECG units, imaging equipment, diagnostic readers | EMI shielding, heat dissipation, sealing integrity |

Structural Frames | Surgical carts, robotic arms, lab analyzers | Load-bearing, tight tolerances, modularity |

Pump and Valve Parts

Industrial pumps and valves must handle pressure, shaking, and heat changes. Die casting lets companies make many parts with tricky shapes. The die gives great size accuracy and strength. Aluminum die casting and magnesium die casting both resist wear and heat. These die casting materials help pumps and valves last longer in hard places.

Good die cast pump and valve parts help systems work well and stay safe. New die casting methods and strict checks make sure every part is good. Extra steps like CNC machining and coatings add more protection and help parts work better.

Die casting helps make lots of parts fast.

The die casting process makes parts with tricky shapes.

Die casting materials like A356-T6 aluminum and ZA-12 zinc-aluminum fight wear and heat.

Quality checks make sure parts work safely.

Laboratory Equipment

Labs use die casting to make strong and exact equipment. The die shapes parts for analyzers, mixers, and robots. Aluminum die casting and magnesium die casting make parts light and tough. The die casting mold gives each part a smooth surface, which helps with cleaning.

Die casting lets companies add details like mounting spots and channels. Extra steps, like CNC machining and powder coating, make each part look perfect. Die casting materials help lab equipment last and handle cleaning every day.

Tip: Companies pick die casting for medical and industrial parts because it is fast, accurate, and gives a great finish.

Materials for Die Cast Parts

Picking the right die casting materials is very important. It helps make parts that are strong and last a long time. The die casting process uses different metals for different jobs. Each metal has special features. These features help the die make parts with the right strength, weight, and look.

Aluminum Alloys

Aluminum die casting is used a lot. It makes parts that are both light and strong. The die shapes aluminum into many things, like car and electronic parts. Some common aluminum alloys used in die casting are:

A380: This alloy is light and can be used for many things, like machines and electronics.

A360: This alloy does not rust easily and stays strong in heat, so it is good for boat parts.

B390: This alloy does not wear out fast, so it is used for engine blocks in cars.

A413: This alloy is easy to shape and strong, so it is used for electrical parts.

Aluminum die casting makes parts that last and do not rust. The die can make thin and tricky shapes with these alloys.

Zinc Alloys

Zinc alloys are good for die casting because they fill the die well. They make parts with lots of detail. Zinc alloys also help tools last longer and cost less than some other metals. The table below shows how zinc alloys are different from other die casting materials:

Material Comparison | Advantages of Zinc Alloys | Disadvantages of Competing Materials |

|---|---|---|

Aluminium | Zinc alloys are more exact, tools last longer, stronger when hit, and cost less | Needs more shaping, not as tight under pressure |

Cast Iron | Zinc alloys cost less, are more exact, and conduct electricity better | Not as useful for many jobs |

Brass | Zinc alloys are strong and easy to shape | Brass costs more and does not fight rust as well |

Magnesium | Zinc alloys are exact and strong | Magnesium is not as strong and does not fight rust as well |

Zinc alloys help make small and tricky parts for electronics and connectors.

Magnesium Alloys

Magnesium is the lightest metal used in die casting. The die shapes magnesium into parts that are light but still strong. Magnesium die-cast parts do not rust easily, which is good in wet places. Some good things about magnesium alloys are:

They help cars and planes weigh less.

They are strong for tough jobs.

They help cars use less gas and pollute less.

They make products better for the environment by being lighter.

The die casting process uses magnesium to make parts for cars and planes.

Material Selection Factors

Choosing die casting materials depends on many things. Engineers think about what each part needs. Then they pick the best metal for the die. Some important things to think about are:

Find the best mix of how well it works, how easy it is to make, and the cost.

Think about what aluminum, magnesium, and zinc can do.

Check if you need to make a lot of parts.

Other things to look at are how strong the metal is, if it rusts, and how well the die can shape it. The die casting process lets companies pick the best material for each part.

Tip: The right die casting materials help make parts that are strong, light, and last a long time.

Advantages of Die Casting

Precision and Complexity

Die casting can make parts with very exact shapes. The process pushes hot metal into a die using high pressure. This helps engineers make parts with tight fits and small details. Other ways, like forging or machining, cannot match this detail. Die casting makes parts with fewer mistakes and better accuracy. The die shapes each part so it fits just right. Small features and thin walls are easy to make. Die casting tooling keeps this accuracy for many parts. Companies pick die casting when they need perfect and reliable parts.

Efficiency and Cost

Die casting is fast and saves money, especially for big orders. Each part can be made in 30 seconds to 1 minute. This is much quicker than sand casting or other old ways. Die casting is great for making lots of parts because it keeps working with little stopping. When more parts are made, each one costs less. Die casting uses just enough metal, so there is little waste. Not much extra work is needed after, which saves time and money. Aluminum, zinc, and magnesium die casting help keep costs down and parts strong.

Die casting makes each part cheaper as more are made.

The process needs little extra work, so it saves time and money.

It cuts down on waste because the die is very exact.

Surface Finish and Strength

Die casting makes parts with smooth surfaces right from the die. Most parts do not need much extra finishing. This is good for electronics, cars, and medical devices. Die casting also makes strong parts with tricky shapes. The table below shows how die casting and machining compare:

Characteristic | Die Cast Parts | Machined Parts |

|---|---|---|

Tolerances | ±0.1 mm for every 25 mm | ±0.025 mm |

Surface Finish | Excellent straight from die | Achieves lower Ra values |

Ideal Applications | High-volume production | High-performance applications |

Die casting materials give the strength needed for many jobs. Companies like MORELUX use new die casting methods to meet tough rules. Their skill helps fix problems like not enough raw materials and shipping issues.

MORELUX gives full solutions, from design to making parts, so die casting is faster and more dependable for every customer.

Die casting is used in many fields, like cars, buildings, hospitals, energy, and electronics. The table below lists what each industry uses die casting for:

Industry | Key Applications |

|---|---|

Automotive | Engine blocks, wheels, suspension parts |

Construction | Window frames, building frames |

Healthcare | Medical devices, diagnostic equipment |

Energy Sector | Wind turbines, solar panel brackets |

Electronics | Enclosures for smartphones and computers |

The material picked changes how strong, tough, and costly a part is. Companies such as MORELUX use HPDC to give good quality, custom parts, and expert help.