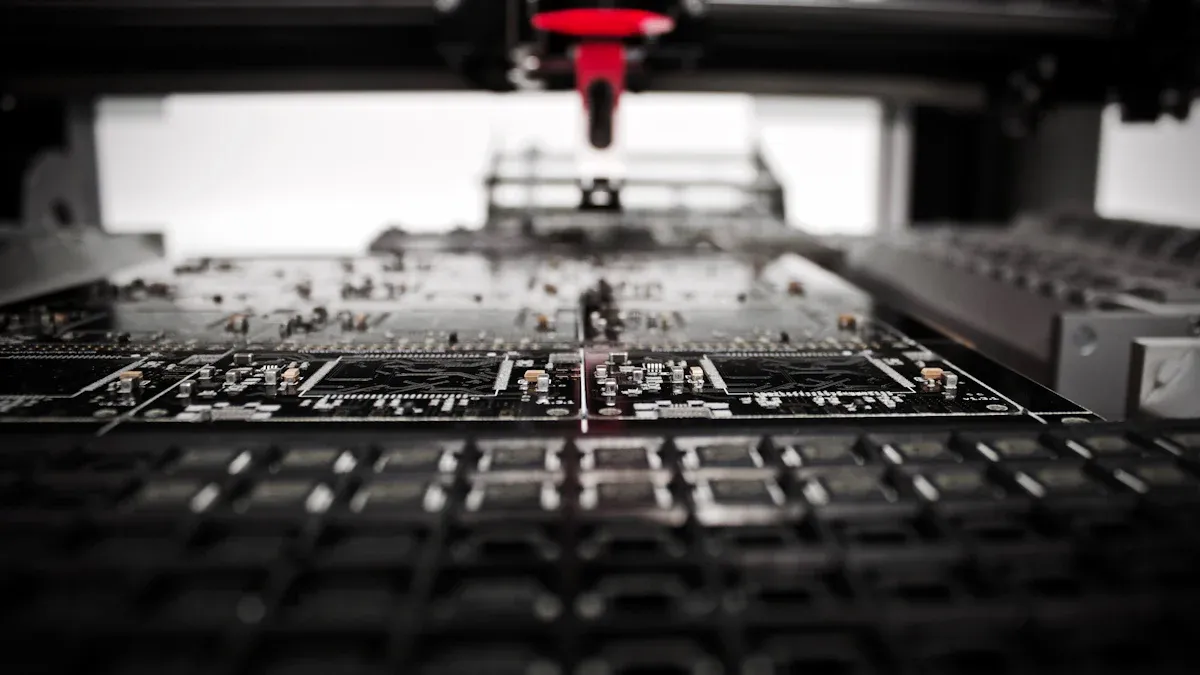

Zinc die-casting is very important in making electronics. This process produces highly precise parts with tight tolerances, ensuring consistent high quality for every component, a level of precision often matched by medical die-castings. Zinc offers strong electrical conductivity and excellent EMI shielding, which is crucial for sensitive devices. Manufacturers choose electronics die-castings made from zinc because the material is durable and long-lasting. It also resists rust, protecting parts in harsh environments. The process allows for complex shapes and smooth surfaces, reducing the need for extra finishing work. The process is fast, and zinc is recyclable, making it both cost-effective and environmentally friendly.

Key Takeaways

- Zinc alloy die casting makes strong parts. These parts are very exact and fit well. They last a long time in electronics.

- This process is fast and saves money. It uses less material and makes less waste. The molds last a long time, so manufacturers save money.

- Zinc alloys do not rust easily. They help protect electronics from bad weather. They also stop damage from interference.

- This method lets you make complex shapes. You can have thin walls and smooth surfaces. This means less extra work and better quality.

- Zinc can be recycled and is good for the planet. It is a smart choice for making electronics in a green way.

Key Properties of Zinc Alloys Used in Electronic

Strength and Durability of Zinc Alloys in Electronics

Zinc alloys are very strong and last a long time. They are great for electronic parts that need to be tough. These parts can handle bumps, scratches, and daily use. The table below shows how strong different zinc alloys are:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Elongation (%) |

|---|---|---|---|---|

| Zamak 3 | 230-270 | 150-200 | 82-91 | 2-5 |

| Zamak 5 | 290-320 | 230-260 | 85-96 | 2-5 |

| Zamak 2 | 280-320 | 220-250 | 105-125 | 2-5 |

| ZA-8 | 250-290 | 170-220 | 80-90 | 2-5 |

| ZA-27 | 310-365 | 200-230 | 130-160 | 2-5 |

| ZA-12 | 235-275 | 150-180 | 80-100 | 2-5 |

Zinc alloys stay strong even after being used many times. This helps electronics work well for a long time.

Dimensional Accuracy in Electronics

Zinc castings are made with very exact sizes. This is important for small electronic parts. Zinc alloys help make parts that fit together just right. They can be made as close as ±0.05 mm. This means parts work well and do not need much fixing. Zinc alloys do not shrink much, only about 0.4% to 0.7%. This helps keep the parts the right size and shape.

Electrical and Thermal Conductivity Benefits

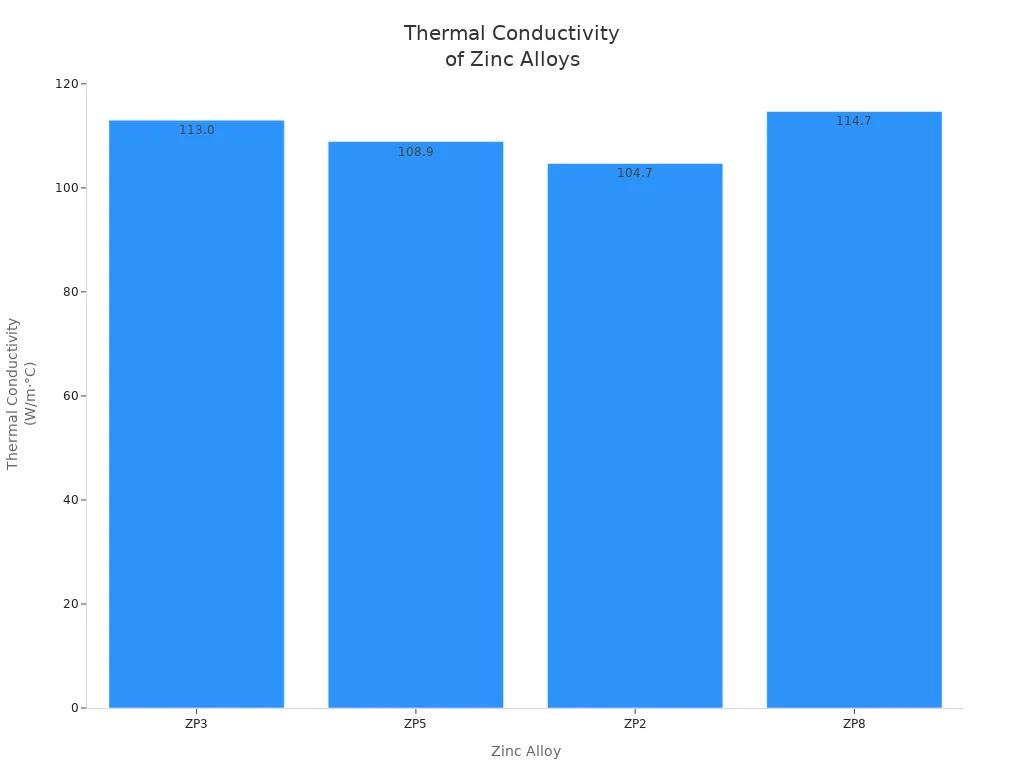

Zinc alloys let electricity and heat move through them well. This helps keep electronics cool and working right. Aluminum alloys let electricity flow better, but zinc alloys are still good. They are strong and easy to shape. The chart below shows how well different zinc alloys move heat:

These features help electronics stay safe and work well.

Corrosion Resistance in Electronics

Zinc alloys do not rust easily. They make a layer that protects parts from water and bad weather. With chromate treatment, zinc alloys can last over 1500 hours in salt spray tests. This helps electronics last longer and stay strong.

Environmental and Recycling Benefits

Zinc alloys are good for the environment. Zinc is easy to find and safe to use. It can be recycled over and over without losing quality. Making zinc parts uses less energy than making aluminum parts. Most leftover zinc is reused in factories. Zinc alloys also follow rules like RoHS. This makes them a smart choice for making electronics.

Major Advantages of Using Die Casting for Electronic

Enhanced Design Flexibility for Complex Electronic Components

Zinc die casting lets engineers make many different designs. The process pushes hot zinc into steel molds using high pressure. This makes parts with thin walls and small details. Designers can put many features into one part, like studs or threads. This means fewer steps to put things together and saves money. Zinc melts at a low temperature, so it is easy to change designs fast. The process can make shapes that other ways cannot. Zinc alloy die casting also makes strong parts that last a long time and do not break easily.

Tip: Zinc die casting lets you make holes of any drill size. It also allows built-in ways to fasten parts, which is great for tricky electronics.

Manufacturing Efficiency in Electronic Die Casting

Zinc die casting is fast and works well. Zinc melts at a low temperature and flows easily. This means parts can be made quickly. The hot chamber process for zinc is much faster than for aluminum. Zinc alloy die casting can be up to ten times quicker than aluminum. This helps make lots of parts fast and saves time on each one. Machines can do much of the work, so parts are made the same every time. The process makes less waste and needs fewer extra steps, so it is a good choice for making electronics.

| Feature | Zinc Alloy Die Casting | Aluminum Die Casting |

|---|---|---|

| Cycle Time | Very fast (hot chamber) | Slower (cold chamber) |

| Mold Longevity | Over a million cycles | Shorter due to thermal stress |

Significant Cost Savings Achieved Through Zinc Alloy Die Casting in Electronics

Zinc die casting helps save a lot of money for electronics makers. It can make tricky shapes with thin walls, so there is less work to put parts together. Fastening features can be made right in the part, so fewer extra steps are needed. Zinc flows well, so parts come out just right and do not need much cutting. The molds last a long time, so many parts can be made before needing new molds. Zinc is easy to find and can be used again, so it costs less. Making lots of parts at once with zinc die casting makes each part cheaper.

- Less waste and scrap

- Uses less energy because zinc melts easily

- Fewer extra steps to finish parts

- Zinc castings last longer, so less fixing and replacing

Superior Surface Finish and Aesthetics

Zinc die casting makes parts with smooth surfaces that need little extra work. Zinc alloys copy mold details very well, so parts look nice right away. This matters for electronics, where looks and how things work are both important. Zinc parts can be coated, painted, or plated easily, which makes them look better and stops rust. Zinc alloys are easier to cut than aluminum and do not wear out tools as fast, so surfaces stay smooth. Electronics makers like zinc alloy die casting for parts that must look good and block interference.

Note: Zinc die casting makes sure electronic cases and connectors look nice and keep important parts safe from outside signals.

Electronic Zinc Alloy Die Casting Benefits

Optimal Application Fit for Electronic Components and Assemblies

Zinc alloys have special features that make them great for electronic zinc alloy die casting. They are strong, keep their shape well, and do not rust easily. Engineers use zinc alloy casting to make parts that last through daily use and tough weather. Zinc alloys can be shaped into thin and tricky designs. This helps companies build small and detailed parts that are still strong.

Many electronics use zinc die casting because of these good points. Some common parts made with zinc alloys are:

- Electrical connectors and terminals need to carry electricity and be strong.

- Extension cord outlets must look nice and last a long time.

- Heat sinks and electrical boxes use zinc because it moves heat well.

- Cell phone cases and laptop frames need to be light, strong, and smooth.

- Outdoor electrical parts need to fight off rust.

- Electric motor, computer, and hand tool parts need to be tough and fit right.

Note: Deco Products and other top companies use electronic zinc alloy die casting to make strong and good-looking extension cord outlets.

These examples show that zinc alloys help electronics work well and look good.

Performance Benefits of Zinc Alloy Die Casting in Electronics

Zinc alloys work really well in electronic zinc alloy die casting. They have features that make them better than many other materials. Zinc die cast parts are strong, tough, and do not wear out fast. This means electronic parts can handle lots of use and pressure.

The table below shows how zinc alloy casting compares to other materials:

| Performance Metric | Zinc Alloy Die Cast Components | Comparison to Other Materials |

|---|---|---|

| Tensile Strength | Up to 2.5 times higher yield strength than aluminum alloys; matches or exceeds most cast irons | Significantly stronger than aluminum and magnesium alloys |

| Rigidity | Higher than aluminum and magnesium alloys; much higher than plastics | More rigid, allowing reduced volume and weight |

| Toughness & Ductility | High impact strength and good ductility; better fracture toughness than aluminum and cast irons | Superior impact resistance and ductility |

| Hardness (Brinell) | Up to 125 BHN (EZAC alloy); typical 95-122 BHN for cold chamber alloys | Much harder than aluminum alloys (70-85 BHN) and engineered plastics |

| Fatigue Strength | Better fatigue performance than plastics; comparable or better than aluminum alloys with higher Al and Cu content | More durable under cyclic loading |

| Conductivity | Good electrical and thermal conductivity; suitable for heat sinks and EMI/RFI shielding | Comparable or better conductivity than many die cast materials |

| Tool Life | Lower melting point extends tool life significantly compared to aluminum alloys | Longer tooling life reduces costs and downtime |

| Surface Finish | Smooth surface finish due to high fluidity; easier to coat or use raw finish | Better finish quality than many competing materials |

| Corrosion Resistance | Natural corrosion resistance with protective patina formation | Superior to many metals without additional coatings |

Zinc alloys keep their shape well. They do not change size much when hot or cold. This helps parts fit together and stay the right shape. This is important for connectors and cases that protect electronics.

Zinc makes a layer on its surface that stops rust and damage. This helps electronic zinc alloy die casting parts last longer, even outside. Special coatings can make them even stronger and stop wear.

Zinc is good at carrying electricity and heat. This makes it a top pick for connectors, terminals, and heat sinks. Zinc also blocks signals that can mess up circuits.

Zinc melts at a low temperature, so tools last longer. Some tools can be used over a million times. This means less time fixing machines and lower costs. Zinc flows well, so it can make thin and detailed parts. This means less extra work is needed.

Zinc die cast parts are good for the planet. Zinc can be recycled almost forever without losing quality. This makes electronic zinc alloy die casting a smart and green choice for electronics.

Tip: Companies can save money and get great results by using zinc alloys for custom zinc die cast parts.

Zinc Die Casting vs. Alternatives

Aluminum Comparison

Zinc die casting is different from aluminum for electronics. Zinc alloys melt at lower temperatures. This lets factories use the hot chamber process. The hot chamber process makes parts faster and uses less energy. Zinc molds last a long time, over 1,000,000 uses. Aluminum molds last about 100,000 uses. Zinc die casting makes stronger parts, up to 2.5 times stronger than aluminum. Zinc parts have smooth surfaces and do not rust easily. This is good for small, detailed electronic parts.

| Aspect | Zinc Die Casting | Aluminum Die Casting |

|---|---|---|

| Strength | 2.5x stronger than aluminum; greater durability | Better strength-to-weight ratio |

| Cost | Lower due to faster cycles and longer mold life | Higher due to slower cycles and shorter mold life |

| Mold Life | Over 1,000,000 shots | About 100,000 shots |

| Cycle Time | 150-200% faster | Slower |

| Surface Finish & Corrosion Resistance | Smoother, more resistant | Good, but less smooth |

Aluminum is better at moving heat and electricity. This makes it good for heat sinks and EMI shielding. But zinc die casting is tougher and saves money for most electronic cases and connectors.

Magnesium Comparison

Magnesium die casting makes very light parts. Magnesium is about 1.8 g/cm³. Zinc alloys are heavier at 7.14 g/cm³. But zinc is stronger and harder than magnesium. Magnesium has a high strength-to-weight ratio and handles heat well. This helps keep electronics cool. But magnesium parts cost more to make. The machines and materials are expensive.

- Magnesium is best for light, heat-resistant electronic parts.

- Zinc die casting costs less for making many parts.

- Zinc alloys are better at handling bumps and last longer.

- Magnesium needs special care because it reacts easily.

Both zinc and magnesium use the hot chamber process. This means they are made quickly and molds last a long time. Still, zinc die casting is better for strong, exact, and cheap electronic parts.

Copper Alloy Comparison

Zinc die casting and copper alloys both fight rust. But zinc alloys make a layer that protects them even more. Zinc coatings last for years and do not crack or peel, even in tough places. Copper plating needs a clear coat to stop rust. Zinc is also better against acids and bases. Copper can get damaged by salt water and acids.

- Zinc plating protects better than copper plating.

- Zinc alloys last longer against weather, chemicals, and wear.

- Copper needs extra coating to last as long as zinc.

For electronic parts that need to be strong and last, zinc die casting is better at stopping rust and lasting longer than copper alloys.

Zinc alloy die casting is a great pick for making electronics.

- It helps protect devices from EMI and cuts down on shaking.

- The process lets you make strong parts with thin walls and tricky shapes.

- Zinc alloys are good at carrying electricity, fighting rust, and look smooth.

- Companies save money and can make parts quickly.

| Property | Benefit |

|---|---|

| Electrical Conductivity | Stops EMI and RFI from hurting devices |

| Corrosion Resistance | Makes parts last longer |

| Precision | Makes small, detailed parts fit just right |

People who make electronics can trust zinc alloys. The parts are tough, work well, and look nice.

FAQ

What makes zinc alloy die casting ideal for electronics?

Zinc alloy die casting makes parts that fit very well. These parts are strong and last a long time. The process can make shapes that are tricky or thin. Zinc alloys do not rust and let electricity move through them. Companies use zinc because it saves money and is quick to make.

Can zinc alloy die cast parts be recycled?

Yes, zinc alloys can be used again and again. Factories melt leftover zinc and use it to make new parts. The quality stays the same each time. This helps make less trash and is better for the planet.

How does zinc die casting compare to aluminum for electronics?

Zinc die casting is faster than aluminum. The molds for zinc last longer too. Zinc parts are stronger and look smoother. Aluminum is good for heat sinks. But zinc is better for most cases and connectors.

Are zinc die cast parts safe for outdoor electronics?

Zinc alloys do not rust or get hurt by weather. Many outdoor electronics use zinc die casting to stay safe. Special coatings can help protect even more in tough places.

What electronic components use zinc alloy die casting?

- Electrical connectors

- Extension cord outlets

- Heat sinks

- Device housings

- Laptop frames

Note: Zinc die casting works for both small and big electronic parts.