Telecom Die Casting

In the fast-evolving telecommunications industry, reliable and high-quality components are crucial. MORELUX offers specialized die casting solutions designed specifically to meet the rigorous demands of telecom devices. With over 20 years of expertise, MORELUX combines advanced technology and precision manufacturing to deliver outstanding die casting products that enhance performance and protection for telecom equipment.

Our expertise extends to critical telecom infrastructure, including components for network enclosures, base stations, antennas, and transmission equipment. Especially the use of aluminum die-cast provides superior durability, shielding, and heat dissipation—key factors in maintaining optimal device performance and long-term reliability.

Contact MORELUX today to discover how our telecom die casting solutions can elevate your products and power your brand’s success in the fast-moving world of telecommunications.

Why Die Casting is Essential for Telecommunications

Telecom equipment often operates in challenging settings, facing exposure to dust, moisture, and electromagnetic interference.

Components must have excellent heat dissipation, be corrosion-resistant, and provide shielding to ensure device reliability and longevity.

Die casting is vital in this sector because it enables the production of parts that meet these high standards efficiently.

Advantages of Die Casting

for Telecom Equipment

- Excellent heat dissipation: Aluminum die casting offers superior thermal management. This is critical for telecommunications devices which often handle high power and generate heat. Effective heat dissipation prevents overheating and ensures stable device operation.

- Corrosion resistance: Die cast aluminum parts resist corrosion well, which protects telecom components from moisture, humidity, and environmental contaminants. This resilience prolongs equipment lifespan especially in outdoor or harsh climate deployments.

- High precision and accuracy: Die casting produces parts with precise dimensions and tight tolerances needed for telecom equipment. This ensures components fit perfectly and perform reliably in complex assemblies such as base stations, antennas, and network hardware.

- Durability and mechanical strength: The Die Casting process produces exceptionally strong and robust components that are specifically designed to withstand vibrations, shocks, and various types of mechanical stress commonly encountered in telecom infrastructure environments.

- Shielding against electromagnetic interference: Die cast metal enclosures naturally provide excellent EMI shielding. This protects sensitive telecom electronics from external electromagnetic noise and prevents signal degradation and device malfunctions reliably.

- Cost-effectiveness: Particularly for large production volumes, die casting provides a highly economical and efficient method to manufacture high-quality, uniform parts. This process maintains consistent quality throughout production while significantly reducing overall manufacturing costs.

Different Die Cast Technologies for Telecom Devices by MORELUX

At MORELUX, we carefully select the best die casting technology based on the requirements of each telecom device project. Our expertise allows us to deliver reliable, high-performance parts that support the fast-evolving telecom industry. We are committed to quality, innovation, and customer satisfaction in every part we produce.

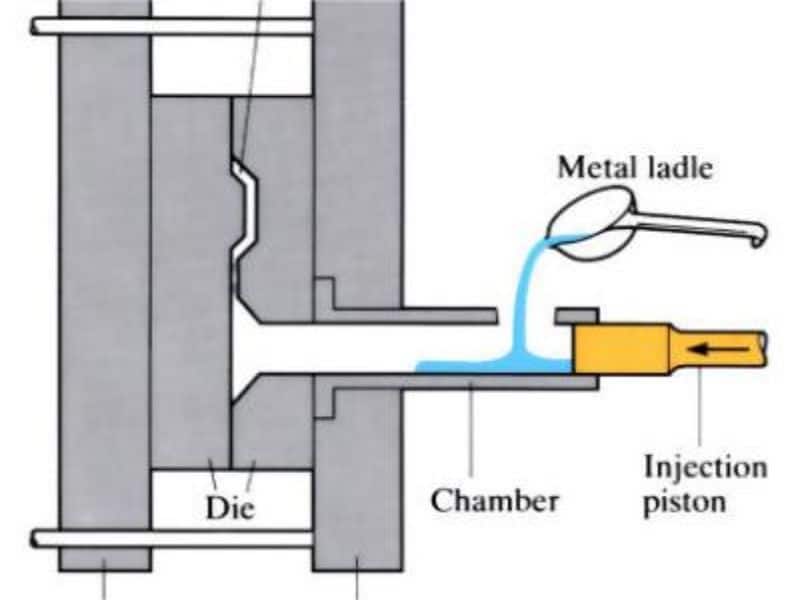

High Pressure Die Casting

This method involves forcing molten metal into precise molds under very high pressure. We use this process to produce thin-walled, intricate telecom housings that require dimensional accuracy and smooth finishes.

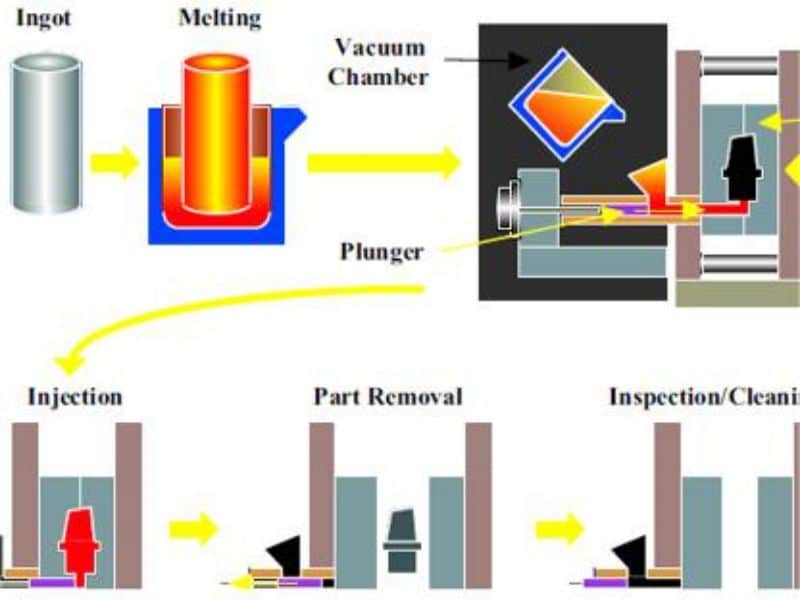

Vacuum Die Casting

Vacuum die casting removes air and gases before injection to reduce porosity. This results in stronger, denser parts suited for critical telecom components needing superior mechanical properties and corrosion resistance.

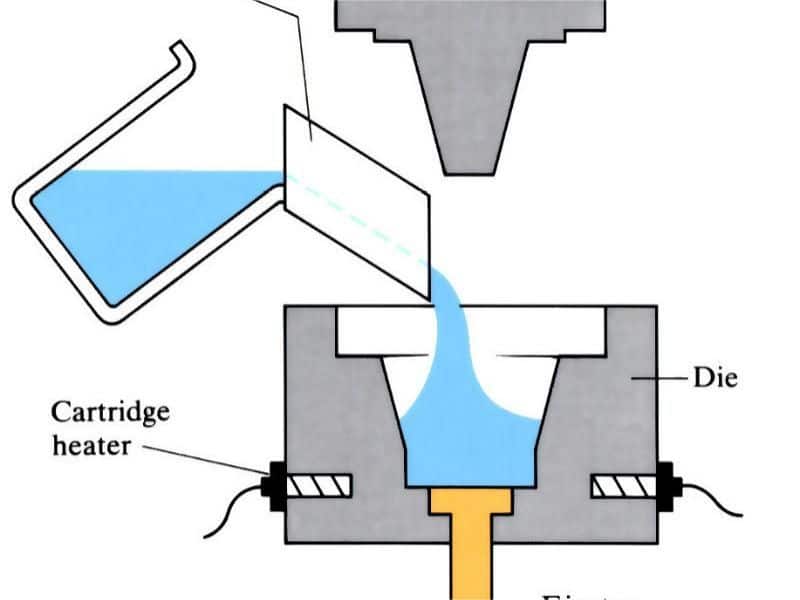

Squeeze Die Casting

Squeeze casting applies pressure throughout solidification, producing fine-grained, highly reliable parts. MORELUX employs it for components demanding exceptional toughness, such as connector housings and shielding boxes.

Materials Used in Telecom Die Castings

At MORELUX, we combine advanced technology with high-grade materials. Our aluminum, zinc, and copper alloy die castings meet the demanding needs of telecom companies. We help deliver components that are strong, precise, and long-lasting. By choosing MORELUX, the telecom industry gains trusted materials that support innovation and performance.

Aluminum Die Castings for Telecom Parts

- 1. Aluminum alloys (MORELUX use commonly ADC12, A6061, A380, A383, A360) are widely used due to their excellent strength-to-weight ratio, good thermal conductivity, corrosion resistance, and recyclability.

- 2. With a thermal conductivity of 180 W/(m·K) or higher, our aluminum castings effectively dissipate heat from high-power components such as 5G base station power amplifiers.

- 3. Aluminum castings are lightweight (density ~2.7 g/cm³, about 50% lighter than zinc), contributing to lighter telecom products such as mobile phone frames and 5G network equipment housings.

- 4. Our die castings also ensure high dimensional stability and can be anodized to enhance surface protection and appearance.

- 5. Aluminum alloys maintain mechanical properties at high and low temperatures. MORELUX controls casting processes carefully to prevent defects like shrinkage cavities and sticking to molds.

Zinc Die Cast Telecommunication Components

- 1. Zinc alloys (our products made from alloys like Zamak 3, Zamak 5, ZA-8) are favored for their high tensile strength, impact toughness, hardness, and excellent casting fluidity, ideal for intricate, thin-walled, and precise telecom parts like connectors and shielding covers.

- 2. Zinc has excellent electrical and thermal conductivity and strong electromagnetic shielding effectiveness (≥60 dB), essential to block signal interference in devices such as routers.

- 3. Our zinc castings have superior surface finishes that usually require minimal post-processing, helping to reduce costs and lead times.

- 4. Zinc is cost-effective and easy to cast due to its low melting point (~385°C), with a longer die life compared to aluminum, balancing cost and precision.

- 5. Although zinc is heavier and less corrosion resistant than aluminum, it remains a cost-effective choice that balances precision and durability. MORELUX is committed to delivering zinc alloy solutions of telecom.

Copper Alloy for Telecom Casting Components

- 1. At MORELUX, we specialize in high-quality copper alloy die casting for telecom. Our products offer excellent electrical and thermal conductivity, reducing power loss and ensuring reliable signal transmission.

- 2. We use advanced alloys like beryllium copper (BeCu), known for high strength, conductivity, non-sparking properties, and miniaturization, perfect for connectors, switches, and fiber-optic parts.

- 3. Our copper alloys provide strong mechanical durability. Adding beryllium, nickel, and tin enhances wear resistance without losing conductivity, supporting the longevity of compact telecom components.

- 4. Corrosion resistance is key. Copper-nickel alloys withstand harsh conditions like saltwater, ideal for outdoor and underwater telecom setups.

- 5. Our alloys are also easy to form and join. We deliver precise die casting with excellent machinability and compatibility with soldering, brazing, or fastening, enabling efficient production of complex telecom parts.

MORELUX Die Casting Manufacturer

to Create Top Telecom Solutions

MORELUX is professional in the die casting process and are proud to offer high-quality telecommunications products for your unique projects and applications. From design, manufacturing, quality control, and delivery, we ensure a comprehensive service that will take your business to new heights.

For more information about our capabilities, contact us today. You may also request a quote so we can start your project immediately!

Advanced Die Casting Capability

MORELUX offers die-casting machines with clamping forces ranging from 280 tons to 2000 tons. This capability supports diverse telecom products, from connectors to housings. It meets industry demands for strength and accuracy.

Precision Surface Treatment

We provide various surface treatments to improve part quality. Options include powder coating, anodizing, and plating. These treatments protect components from corrosion and wear. They also give a smooth.

Strict Quality Control Measures

MORELUX uses advanced inspection tools like coordinate measuring machines and X-ray. Each part is checked for dimensional accuracy and defects. Our quality team monitors the entire process from raw material to final product.

Cases of Successful Die-casting projects in Telecommunication

Radio Frequency Connectors and Adapters

Application: Die cast RF connectors and adapters offer excellent mechanical strength and electromagnetic shielding, ensuring optimal signal transmission and durability in high-frequency applications.

Case Study: Production of RF connectors using precision die casting allows for consistent low-reflection designs and integration of insulators to reduce unwanted signal reflections. Custom-die cast insulator structures ensure robust PCB-to-connector launches and improved production yield for millimeter-wave connectors.

Antenna Housings and Waveguides

Application: Die-cast antenna housings deliver lightweight, corrosion-resistant, and dimensionally accurate enclosures for both indoor and outdoor use. Waveguides benefit from the complex, seamless geometries achievable with die casting.

Case Study: Aluminum die casting is utilized for satellite and cellular antenna housings, supporting complex, integrated bracket features, as well as precise, consistent production of large and small antenna components.

Fiber Optic Transceivers and Connector Housings

Application: Housings for fiber optic transceivers require high dimensional precision, durability, and superior thermal management.

Case Study: Advanced fiber optic transceiver modules utilize high-thermal-conductivity aluminum alloy die casting to form lightweight, heat-dissipative housings. Integrated fin structures made during casting improve thermal performance and reduce the need for extra cooling components.

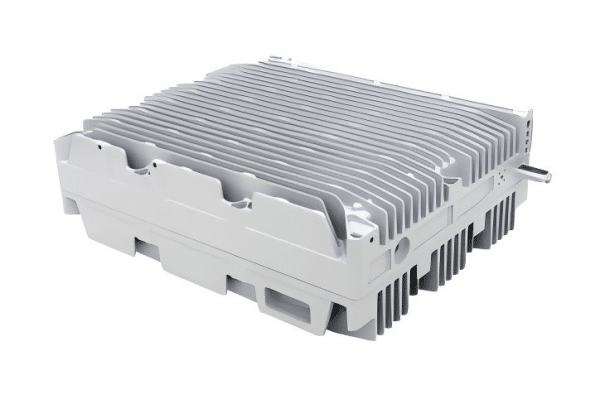

Base Station Casings and Filter Cavities

Application: Base station casings and filter (RF or cavity) housings must withstand environmental stress while providing robust EMI shielding and thermal management.

Case Study: Custom aluminum die-cast housings for 5G base stations are manufactured with complex internal and external geometries, ensuring superior structural durability. Filter cavities benefit from die casting’s ability to meet tight tolerances crucial for RF performance.

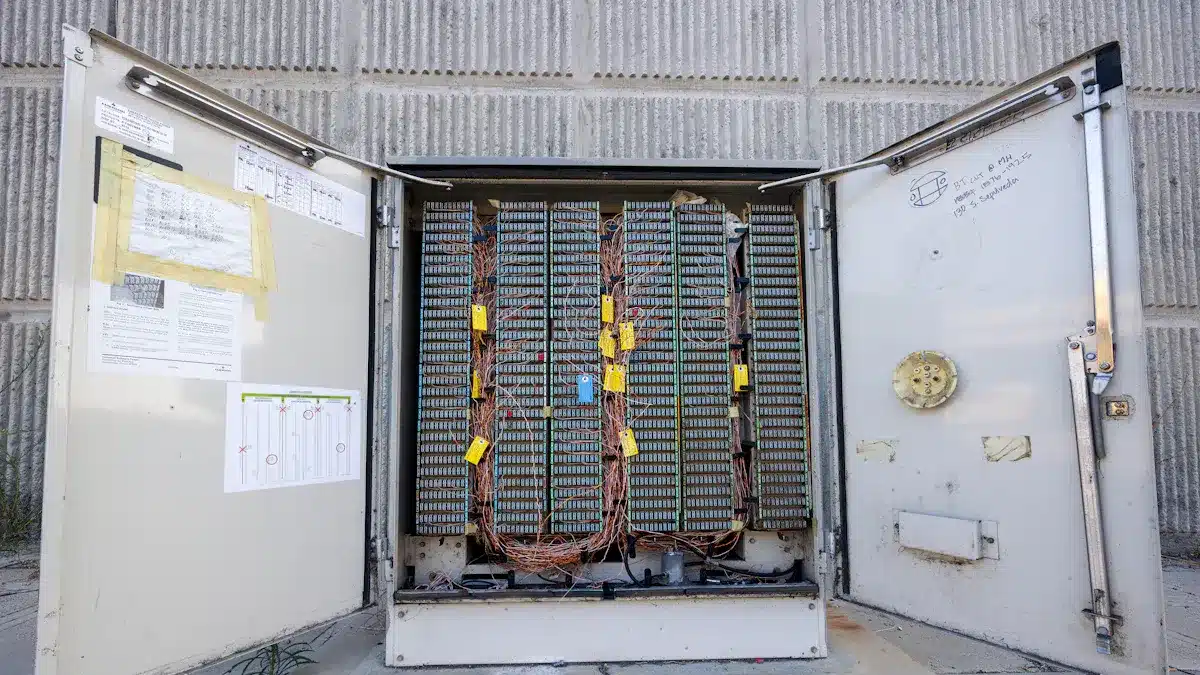

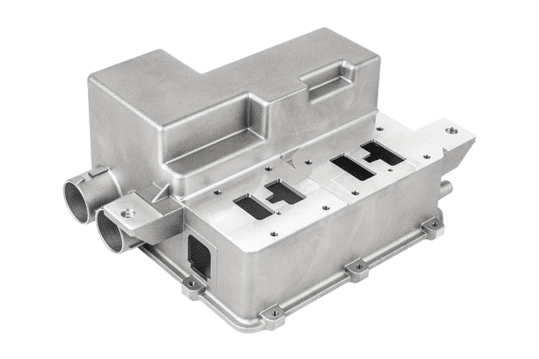

Electronic Enclosures and Shielding Boxes

Application: Die cast enclosures safeguard sensitive circuit boards and modules from moisture, dust, and EMI. Integration of shielding features into the enclosure walls streamlines assembly and enhances protection.

Case Study: Telecommunication companies routinely use die cast ADC12 and A380 aluminum alloys to produce enclosures for electronics, incorporating thin integrated heat sinks, multi-slotted cable outlets, and fine-surface requirements. These enclosures consistently meet industry standards for mechanical protection and EMI/RFI shielding.

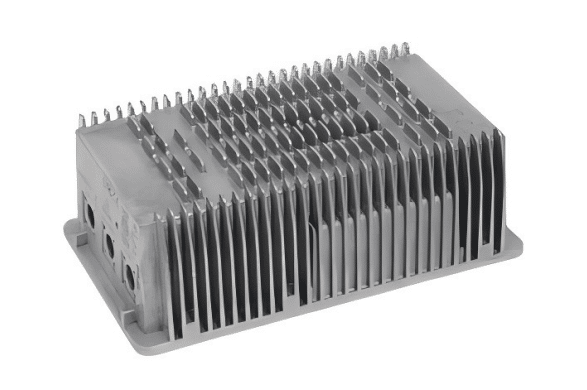

Heat Sinks Integrated within Housing

Application: Many telecom components demand high-efficiency cooling. Die casting allows direct integration of complex heat sink fins within housings, optimizing heat dissipation without compromising structure.

Case Study: Die-cast aluminum housings for telecom power electronics and transceivers feature integrated, high-density fins formed during casting, yielding significant improvements in thermal performance and enabling modular assembly for large-scale cooling needs.