Your Trusted Partner for Custom Die-Casting

Custom Precision Die-Casting Solutions

Die-casting Machines from 280T to 2000T

MORELUX’s dedicated engineering team delivers exceptional expertise in custom precision die-casting, covering every stage from tooling and die casting to machining, finishing, and assembly. Utilizing cutting-edge technology combined with extensive industry experience, our specialists offer innovative solutions tailored to your unique product specifications.

We work closely with you to ensure each component meets the highest standards of quality, accuracy, durability, and efficiency. Choose MORELUX as your trusted partner for comprehensive custom die-casting services that elevate your product performance and manufacturing success.

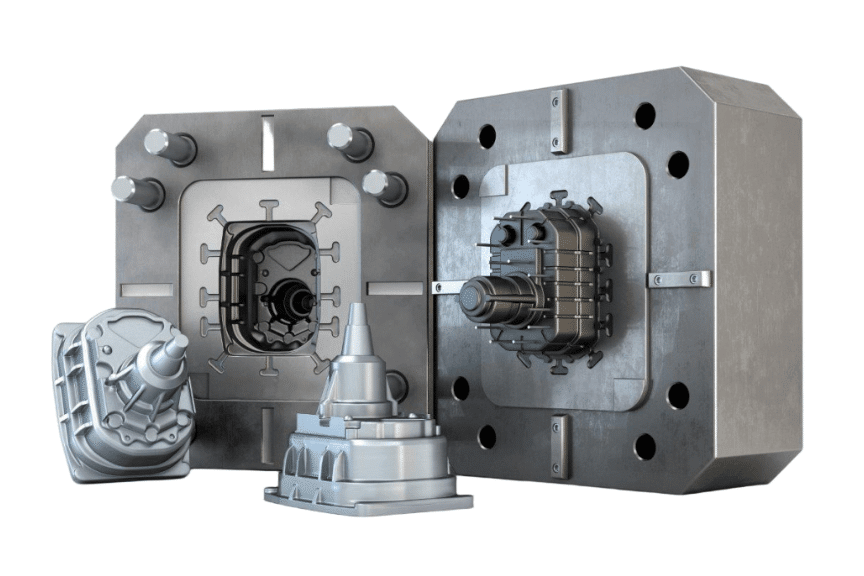

Tooling Design & Manufacturing

At MORELUX, tooling is the foundation of our custom die casting service. We start by designing precise molds using advanced CAD software. Our tooling engineers work closely with clients to ensure every detail matches their specifications. For example, we typically create molds with a tolerance of ±0.02 mm to guarantee accuracy.

We use high-grade steel for durability, allowing the mold to last for over 500,000 casting cycles. The tooling phase usually takes 15 days, depending on the complexity of the part. During this time, we perform simulation tests to optimize mold flow and reduce defects. This careful preparation ensures the die casting process runs smoothly and produces high-quality parts consistently.

High-Quality Die-Casting Production

Once the tooling is ready, we move to the die casting stage. MORELUX specializes in aluminum, zinc, and copper die casting, with machines ranging from 280 to 2000 tons of clamping force. For example, our aluminum die casting machines can inject molten metal at temperatures up to 700°C, producing parts with wall thickness as thin as 0.8 mm.

We maintain strict control over casting parameters such as injection speed, pressure, and cooling time to minimize porosity and improve mechanical strength. On average, we produce 10,000 to 50,000 parts per batch, depending on customer demand. Our quality control team inspects each batch using X-ray and dimensional measurement tools to ensure defect-free products.

Advanced CNC Machining Services

After casting, parts often require machining to achieve precise dimensions and surface finishes. MORELUX uses CNC machines capable of tolerances within ±0.01 mm. For example, we can drill holes as small as 1 mm in diameter and mill complex geometries with high repeatability. Our machining center operates 24/7 to meet tight deadlines, typically machining 80% of our die-cast parts.

We also perform secondary operations such as tapping, threading, and deburring. Real-time monitoring and automated inspection systems ensure that every machined part meets customer specifications. This step enhances the functionality and assembly readiness of the die-cast components.

Professional Surface Finishing Solutions

Finishing is crucial for both aesthetics and protection. MORELUX offers various finishing options including powder coating, anodizing, plating (nickel, chrome), and painting. For example, our anodizing process can produce a uniform oxide layer 15 microns thick, improving corrosion resistance. We use environmentally friendly finishing materials that comply with RoHS standards. Surface roughness after finishing is typically below Ra 0.8 µm, providing a smooth and attractive appearance.

Our finishing team inspects color consistency and adhesion strength to ensure durability. This step not only enhances product lifespan but also meets the visual and functional requirements of diverse industries.

Comprehensive Assembly & Integration

Finally, MORELUX provides assembly services to deliver ready-to-use products. Our skilled technicians assemble components with precision, using automated screwdrivers and ultrasonic welding machines. For example, we can assemble up to 5,000 units per day in our clean assembly lines. We conduct functional tests such as torque checks and electrical continuity tests to guarantee performance. Packaging is customized to protect parts during shipping and handling.

Our integrated process from tooling to assembly ensures shorter lead times and consistent quality. Customers appreciate receiving fully assembled, tested products that are ready for immediate use.