Medical Die Casting

MORELUX is your trusted partner for customized Medical Die Casting solutions. Our expertise, advanced technology, and commitment to quality enable us to deliver precision metal components that meet the demanding needs of the medical industry.

Common metals used in medical die casting include aluminum, zinc, and copper alloys. These metals are chosen for their biocompatibility, strength, corrosion resistance, and lightweight properties.

Whether you need surgical instrument parts, diagnostic equipment housings, or components for patient monitoring devices, MORELUX provides reliable, scalable, and compliant die casting services to help you succeed.

Contact MORELUX today to learn how we can support your next medical device project with our specialized die casting capabilities.

MORELUX Die Castings

Enhancing Medical Device Performance and Reliability

At MORELUX, we specialize in precision die casting that plays a crucial role in advancing medical technology. Our die-cast components deliver exceptional accuracy with tolerances as tight as ±0.05 mm, enabling the creation of intricate and complex geometries essential for modern medical devices.

- High Precision and Complexity: Our advanced die casting processes produce components with exacting dimensions and complex shapes, meeting the stringent requirements of surgical instruments, diagnostic equipment, and implantable devices.

- Cost Efficiency and Sustainability: Automation and minimal material waste in our manufacturing reduce production costs, making high-quality medical components more accessible while supporting sustainable practices.

- Durability and Reliability: MORELUX die-cast parts are engineered for long-lasting performance, significantly reducing the frequency of replacements. This durability translates into improved patient outcomes and lower overall healthcare expenses.

- Sterilization Compatibility: Our components withstand rigorous sterilization methods—including steam autoclaving, gamma radiation, and gas cleaning—ensuring safety and compliance in demanding medical environments.

Why Choose MORELUX As Your Die Casting Manufacturer

Experience and Technology

With 20 years in die casting, MORELUX specializes in medical parts. We use advanced machines and meet strict ISO 13485 standards for reliable, precise production.

Customized Casting Solutions

Every medical device is unique. MORELUX offers tailored die casting services, working closely with clients to design molds and processes that fit exact specifications.

Strict Quality Assurance

Quality is our priority. We perform material certification, inspections, non-destructive testing, and final validation to ensure every part meets high medical standards.

Metal Alloy of Precision Casting Parts for Medical

At MORELUX, we specialize in delivering high-quality die-cast components tailored to the stringent demands of the medical sector. Our expertise spans multiple alloy metals, enabling us to provide customized solutions that enhance the performance, reliability, and safety. Partner with MORELUX for innovative metal die casting parts that advance healthcare technology.

Medical Parts Aluminum Die Casting

MORELUX produces precision die-cast parts using advanced aluminum alloys like A360 and A380.

1. Aluminum is lightweight, which makes it easy to handle and reduces overall device weight.

2. It has excellent resistance to corrosion, helping parts last longer in tough environments.

3. Aluminum is biocompatible, making it safe for use in important medical devices.

4. Aluminum alloys also offer strong EMI (electromagnetic interference) shielding.

5. They provide high dimensional stability, ensuring parts keep their shape and fit precisely.

6. The robustness of aluminum helps protect sensitive electronics and improves long-term reliability of medical equipment.

These aluminum alloy die casting parts are used in critical medical equipment such as:

Diagnostic machines, Respiratory devices, Patient monitoring systems, Durable housings for medical devices

Zinc Alloy Medical Die Castings

MORELUX uses zinc alloys to make parts that are both cost-effective and dimensionally stable. Choosing MORELUX means getting reliable, precise, and cost-efficient solutions for healthcare products.

1. Zinc alloys are known for their smooth surface finish and good compatibility with plating.

2. Zinc die casting allows for very precise parts with tight tolerances and complex shapes.

3. Our zinc alloy parts offer a good balance of low cost and high accuracy.

4. They meet the strict quality standards required in medical device manufacturing.

These make zinc alloys ideal for making parts used in medical devices such as:

Insulin pumps, Surgical instruments, Stethoscopes, Crutches, Seat lifts, Wheelchairs, Respiratory equipment

Copper Alloy Die Castings for Medical Devices

MORELUX understands how important electrical conductivity is for medical devices. We offer copper alloy die castings designed specifically for electrical parts.

1. Our copper parts provide excellent electrical conductivity, which is crucial for device performance.

2. They are also very durable, ensuring long-lasting use in medical equipment.

3. By using our copper die cast components, medical devices can work reliably and safely.

4. MORELUX is committed to delivering high-quality materials that meet the strict demands of the medical industry.

These copper alloy castings are widely used to produce electrical parts for devices like:

ECG machines, patient monitors, and diagnostic equipment.

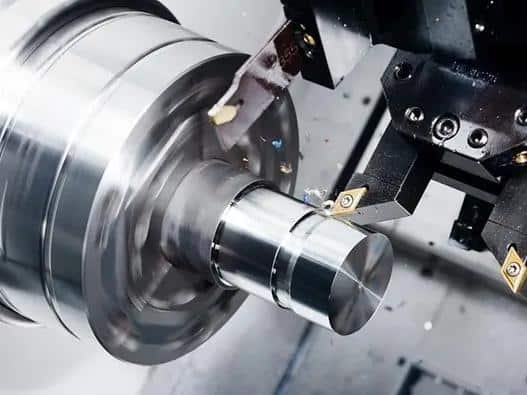

CNC Machining for Medical Castings by MORELUX

By combining high-volume die casting with precision CNC machining, MORELUX delivers reliable, high-quality medical parts that comply with strict regulations. Trust us to help you meet the demanding requirements of the medical industry with expert post-casting machining solutions.

We understand that precision tolerance is crucial for medical die casting parts. Medical devices demand exact dimensions and smooth surfaces to ensure safety and reliable performance. Die casting alone cannot always meet these strict requirements.

That is why we offer advanced CNC machining services after die casting. Our CNC machining process refines the parts with micron-level accuracy, often up to 5 microns (0.0002 inches). This ensures the parts fit perfectly and function safely in critical medical equipment like MRI machines and surgical tools.

Surface Treatment for Medical Grade Die Castings

For medical grade die castings, surface treatments must ensure biocompatibility, corrosion resistance, durability, and ease of cleaning to meet stringent medical standards such as FDA compliance.

Anodizing, parylene coating, conversion coatings, and electropolishing are among the most suitable and widely used surface treatments for medical grade die castings.

If you are selecting a surface treatment for a specific medical device, consider the device’s material, required electrical properties, sterilization methods, and regulatory compliance to choose the optimal finishing process. MORELUX offers specialized surface treatments for die castings in a variety of alloys to improve performance and safety.

- Anodizing: For aluminum die castings, anodizing creates a robust, corrosion-resistant oxide layer that significantly improves durability and wear resistance. Hard anodizing offers superior hardness and smooth finish, ideal for medical devices but lowers electrical conductivity.

- Parylene Coating: MORELUX provides parylene coatings, a biocompatible polymer barrier renowned for its uniform, pinhole-free protection against moisture and chemicals. This coating is extensively used in medical components requiring exceptional biocompatibility and environmental resistance.

- Conversion Coatings: Our chemical film and chromate conversion coatings enhance corrosion resistance while preserving electrical conductivity—critical for medical parts with electrical functionalities. For example, Alocrom chromate coatings offer balanced protection and durability.

- Electropolishing: We offer electropolishing services that refine metal surfaces by removing microscopic layers, significantly boosting corrosion resistance and facilitating sterilization. This process is vital for medical equipment where hygiene and bacterial prevention are paramount.

- Additional Finishes: MORELUX also offers powder coating, painting, and metal plating (chrome, silver) for aesthetics, protection, and function. Silver plating, in particular, is chosen for its antimicrobial properties and excellent electrical conductivity in electronic medical devices.

Applications of Die Casting for Medical Devices

From precision surgical tools and diagnostic machines to implantable components, MORELUX’s die casting expertise supports a wide spectrum of medical devices. We are proud to contribute to innovations that enhance patient care and drive the medical industry forward. Choose MORELUX for die-cast medical components that combine precision, reliability, and cost-effectiveness—empowering healthcare providers and improving lives worldwide.

Surgical Instruments

Die casting is used to manufacture lightweight, strong, and sterilizable tools like forceps, scalpels, scissors, and retractors. The process ensures smooth finishes and consistent quality, essential for repeated use in medical procedures.

Orthopedic and Dental Implants

Implants such as screws, plates, joint replacements, abutments, and brackets are produced using die casting. Biocompatible materials like titanium alloys are commonly used, providing corrosion resistance and high fatigue strength for long-lasting implants inside the body.

Diagnostic and Imaging Equipment

Components for medical devices such as X-ray tube housings, MRI machine parts, and various other diagnostic machines are precisely die cast to withstand extremely high temperatures and demanding operational conditionswhile maintaining precision and durability.

Medical Electronic Equipment

Die casting is used to manufacture high-quality parts for various electronic medical devices, including patient monitors, infusion pumps, defibrillators, and blood pressure monitors, ensuring reliability and precise dimensions for medical applications.

Respiratory and Therapy Equipment

Parts such as casings for oxygen concentrators and artificial respiration devices are manufactured using die casting, which is highly advantageous due to its capability to create intricate, complex shapes while ensuring excellent durability and long-lasting performance.

Hospital Furniture and Aids

Zinc die casting is used for hospital beds, infusion stands, wheelchairs, crutches, and so on. Zinc’s high density and radiation shielding properties make it ideal for patient-contact equipment that requires frequent disinfection without losing functionality or appearance.

More OEM Medical Die Casting Parts

Beyond the above, MORELUX also provide more OEM die-casting parts such as ophthalmic devices, lab and pharmaceutical equipment, robotic systems, and protective medical casings. Our parts feature complex shapes and ergonomic designs to meet medical industry needs.