Lighting Die Casting

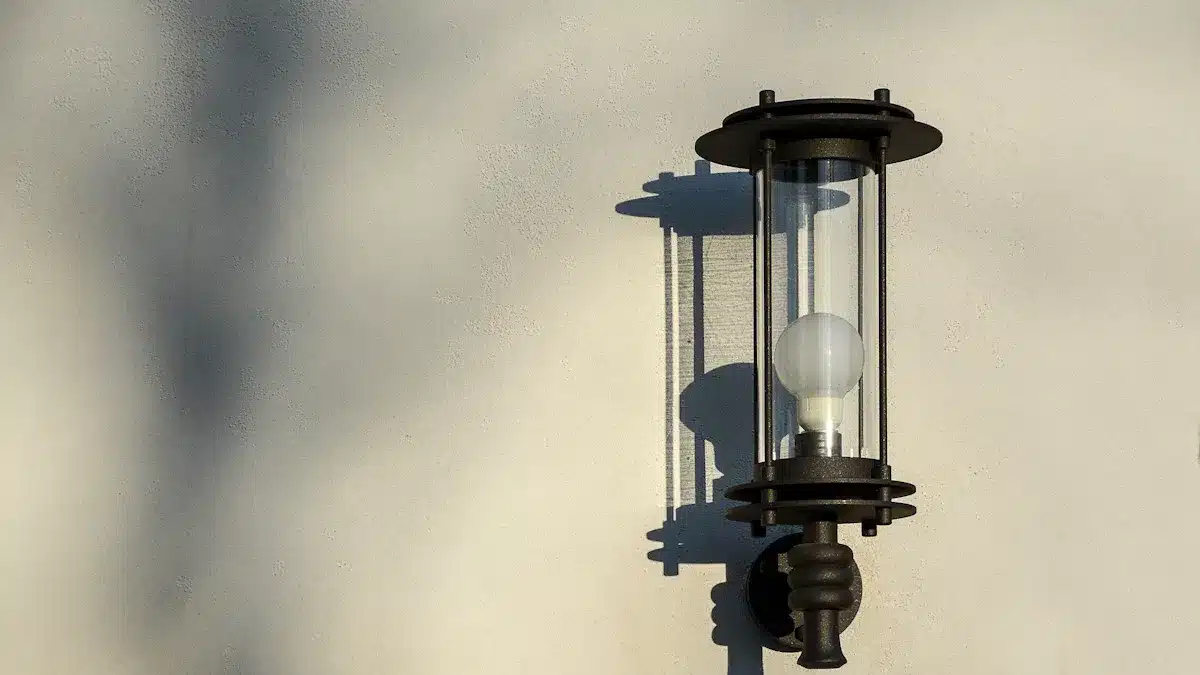

Die casting is a critical manufacturing process for producing high-quality, durable, and precision components essential to modern lighting solutions. From the perspective of Morelux, a seasoned industry leader with over 20 years of expertise, die casting services are tailored specifically to meet the evolving demands of the lighting industry, especially for aluminum components used in LED fixtures and outdoor lighting. Our expertise extends to outdoor lighting fixtures such as wall packs and UV-C air sanitizers, where die-cast aluminum components provide durability and thermal management.

Morelux vertically integrated approach—from initial sketches and 3D modeling to full-scale production and assembly—ensures seamless project management and cost efficiencies. This holistic service model reduces time to market and simplifies supply chains for lighting OEMs.

Contact MORELUX today to discover how our lighting die casting solutions can transform your products and illuminate your brand’s success.

Advantages of Die Casting

in Lighting Industry

- Durability and Corrosion Resistance: Die-cast aluminum parts exhibit excellent resistance to harsh environmental conditions such as rain, snow, and temperature extremes, maintaining structural integrity and appearance over time. This is critical for outdoor lighting fixtures like street lamps and floodlights.

- Precision and Consistency: Die casting offers high dimensional accuracy and smooth surface finishes, enabling the production of complex, thin-walled parts with tight tolerances. This precision reduces the need for post-machining and ensures consistent quality across large production runs.

- Thermal Management: Aluminum and zinc alloys used in die casting have excellent thermal conductivity, which is essential for dissipating heat from LED lighting components. Effective heat management helps prolong the lifespan of LEDs and ensures stable performance, enhancing the overall reliability of lighting products.

- Mechanical Strength: The die casting process involves rapid cooling and solidification under pressure, which improves the mechanical properties of the parts produced. This results in components with enhanced strength and hardness, making them suitable for durable lighting fixtures that can withstand mechanical stress.

- Design Flexibility: The die casting process allows for intricate and complex shapes that are difficult or impossible with other manufacturing methods. This flexibility allows designers to create innovative lighting solutions that combine both functional performance and aesthetic appeal, supporting creative and efficient lighting designs.

MORELUX: Trusted Lighting Die Casting Manufacturer

As a fully integrated manufacturer specializing in custom castings, MORELUX is your reliable partner for lighting casting solutions. With over 20 years of expertise in the lighting industry, including streetlight production and complete die-cast component assembly, we bring extensive experience to every project.

Our strong engineering capabilities allow us to offer design support aimed at enhancing manufacturing efficiency and lowering costs. We provide top-tier services in die-casting, plating, painting, and assembly to meet your needs.

MORELUX accommodates both low-volume and high-volume production runs. Additionally, we offer a variety of non-destructive testing methods—such as X-ray inspection, magnetic particle testing, and dye penetrant testing—to guarantee the highest quality and performance standards.

Casting Production Capacity

MORELUX operates from a modern 750,000 square feet facility with over 600 employees and owns four vertically integrated factories across China and Malaysia.

Advanced Die Casting Equipment

High Precision CNC, EDM, Drilling, Wire Cutting, Die casting machines from 200T to 2000T. 3 Powder Coating Lines with ability to surpass 3000 hrs of salt spray test.

Comprehensive Vertical Integration

We maintain full control over every manufacturing step, from mold design and fabrication to die casting, precision CNC machining, finishing, powder coating, and local assembly.

What Can MORELUX Do for Your Lighting Project

MORELUX can significantly enhance your lighting project by offering comprehensive, state-of-the-art lighting solutions specifically tailored to meet your unique requirements. With advanced technology and expert design, MORELUX ensures optimal illumination, energy efficiency, and aesthetic appeal. Discover how MORELUX can transform your lighting project today.

Fixture Die Castings Manufacturing

- Cover and Back Plates

- Heat Sinks

- Trim plates

- Flanges

- Suspended ceiling light fixtures

- Recessed lighting clips

- Ceiling light mounting plates

- LED light clips

- Light cover clips

- Metal light clips

- More

Surface Treatments for Lighting Fixture

- As Cast

- Painting

- Polishing

- Sand Blasting

- Media Tumbling

- Metal Plating

- Anodizing

- Powder Coating

- Brushed Finish

- Post-machining

- More

Quality Control for Die Cast Lighting

- Vibration Testing

- X-ray Inspection

- Photometric Testing

- Corrosion Salt Testing

- Pressure Testing

- Explosion Testing

- Electrical Function Tests

- Hi-pot Tests

- Grounding tests

- Visual inspections

- More

Popular Die Casting Materials For Lighting Fixtures

The most popular die casting materials for lighting fixtures are primarily aluminum alloys, zinc alloys, and to a lesser extent, copper alloys. Each offers distinct advantages suited to different lighting applications. Aluminum alloys are the premier choice for die-cast lighting fixtures, especially LED housings, due to their optimal combination of mechanical, thermal, and aesthetic properties. Zinc alloys serve well for decorative and intricate parts, while copper is selected for specialized uses.

Aluminum Die Casting Lighting Parts

At MORELUX, we specialize in high-quality aluminum die casting parts for lighting fixtures. Our products use premium aluminum alloys such as AA 380, AA 384, AA 386, and AA 390. These materials offer a perfect balance of strength, durability, and performance.

- Aluminum is lightweight, which helps reduce the overall weight of lighting fixtures, making installation and handling easier.

- Aluminum alloys offer good corrosion resistance, which is essential for both indoor and outdoor lighting applications.

- Aluminum also has high dimensional stability, allowing for the creation of complex shapes and thin walls without warping.

- Its good thermal and electrical conductivity helps dissipate heat generated by lighting components, improving fixture longevity.

- Additionally, aluminum die castings provide good mechanical strength and stiffness, ensuring durability.

- The material is recyclable, which supports environmental sustainability.

Aluminum die cast lighting parts are commonly found in LED floodlights, street lights, panel lights, outdoor fixtures, commercial lighting, decorative lamps, and industrial lighting, where energy efficiency and robustness are critical.

Zinc Lighting Die Castings

At MORELUX, we also specialize in high-quality zinc die casting parts for lighting fixtures. Our products utilize premium zinc alloys such as Zamak #2, #3, #5, and ZA8, chosen for their excellent castability and mechanical performance.

- Zinc is renowned as one of the easiest metals to cast, enabling the production of intricate and precise lighting components with thin walls and fine details.

- Zinc alloys offer high ductility and impact strength, providing durability and toughness suitable for small to medium-sized lighting parts.

- Additionally, zinc die castings exhibit good corrosion resistance and can be easily plated with finishes such as nickel or chromium to enhance both appearance and longevity.

- The relatively low melting point of zinc contributes to cost-effective, high-volume production and extends die life due to favorable casting characteristics.

- Zinc’s mechanical properties ensure reliable performance in applications requiring moderate strength and detailed finishing.

These make zinc ideal for decorative and complex lighting designs. Zinc die cast lighting components are commonly used in small light fittings, multi-light chandeliers, decorative fixtures, and hardware parts where precision and aesthetic appeal are paramount.

Copper Alloy Light Fixture Die Castings

At MORELUX, we also specialize in premium copper alloy die cast parts for lighting fixtures. Our copper-based alloys, including silicon tombac and other high-performance blends, deliver exceptional mechanical strength and corrosion resistance, making them ideal for demanding lighting applications.

- Copper alloys provide outstanding hardness and wear resistance, approaching steel-like durability, which ensures long-lasting reliability for precision lighting components.

- Their excellent dimensional stability allows the production of intricate designs with tight tolerances, essential for high-quality lighting parts.

- With high thermal and electrical conductivity, copper alloy die castings efficiently dissipate heat generated by lighting elements, enhancing fixture lifespan and performance.

- Their inherent corrosion resistance makes them ideal for harsh environments, including industrial and outdoor settings.

Although copper alloys are typically more costly and challenging to cast than aluminum or zinc, they are preferred for lighting fixtures that require enhanced strength, durability, and a premium finish. Copper alloy die cast parts are commonly used in specialized industrial lighting, high-end decorative fixtures, and applications where wear resistance and mechanical robustness are paramount.

Applications of Die Casting in the Lighting Industry

Die casting plays a vital role in the lighting industry by enabling the production of high-quality, durable, and precisely engineered lighting components. Its applications span various lighting sectors, including LED lighting, street and outdoor lighting, decorative fixtures, and industrial lighting.

MORELUX revolutionizes lighting manufacturing by producing reliable, efficient, and visually appealing die casting lighting parts that meet the evolving demands of modern lighting technologies and design trends.

Die Casting Outdoor Lighting

Aluminum die-cast components are favored for outdoor fixtures such as street lamps and garden lights due to their lightweight, corrosion resistance, and durability under harsh environmental conditions. Die casting allows integration of solar panels and smart controls into sleek designs.

Die Casting LED Lighting Lamps

Die casting, especially with aluminum alloys, is extensively used to manufacture heat sinks, housings, casings, and reflectors for LED lights. Aluminum’s excellent thermal conductivity helps dissipate heat efficiently, enhancing LED performance and lifespan.

Die Cast Floodlight Housing

Zinc and aluminum die-cast floodlights and housings provide robust, lightweight solutions for factories, warehouses, retail, and hospitality environments. These components combine durability with precise dimensional accuracy essential for assembly and performance.

Die Cast for Decorative Lighting

The design flexibility of die casting enables the creation of intricate and aesthetically pleasing decorative lighting such as chandeliers, pendant lights, and wall sconces. Complex shapes and fine details can be produced cost-effectively and with consistent quality.