Automotive die-castings is revolutionizing the way cars are made. This process produces car parts that are both lightweight and strong. Over the past decade, manufacturers have increasingly relied on aluminum die-casting instead of traditional iron and steel (and materials like copper die-casting in certain applications) for many vehicle components. These advanced methods help engine parts and other critical car components last longer, while also improving fuel efficiency and reducing emissions.

Key Takeaways

- Aluminum die casting makes car parts strong and light. It also helps them resist rust. This helps cars use less fuel. It also helps cars last longer.

- This process lets people make parts quickly and exactly. It is used for engines, transmissions, brakes, and body parts.

- Using aluminum die casting makes cars safer. It also helps cars work better. It helps lower pollution. This supports a cleaner world.

The Role of Aluminum Die Casting in Manufacturing Automotive Parts

Benefits of Aluminum Die Casting in Automotive

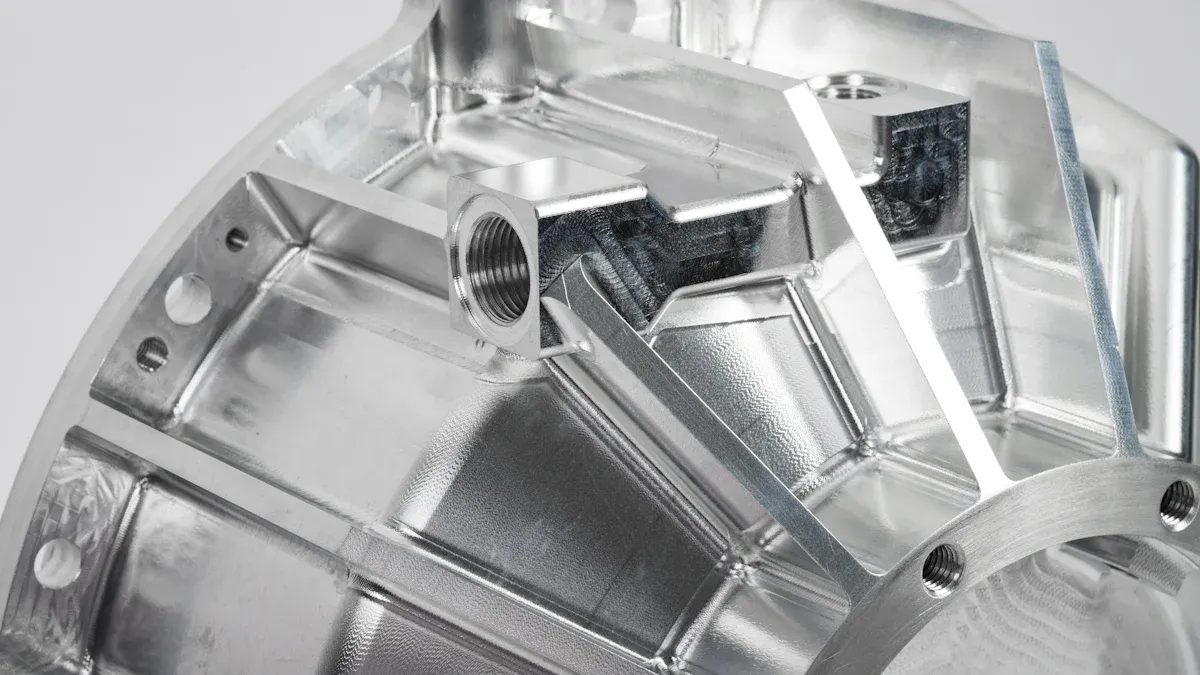

Aluminum die casting helps make important car parts. This process uses hot aluminum pushed into molds with high pressure. It makes parts that are light, strong, and do not rust easily.

Some main benefits are:

- Parts are strong but also light.

- They do not rust fast, so they last longer.

- They help engines and brakes stay cool.

- Making these parts is quick and does not waste much.

- The parts are made very exact and smooth.

- Lighter parts make cars use less gas and pollute less.

- This process is good for making many parts fast.

Aluminum die casting lets car makers build lighter parts. These parts help cars meet rules for the environment and work better.

Aluminum Alloy Materials Used in Automotive Die-casting Parts

Car makers use special alloys for aluminum die casting. The most used ones are A380, A383, A360, and A413. Each alloy is good for different car parts.

| Aluminum Alloy | Common Use in Automotive Die Casting | Key Properties |

|---|---|---|

| A380 | Engine blocks, transmission cases, structural parts | Good strength, easy to cast, does not rust, light |

| A383 | Small, detailed parts | Strong, does not crack, good for tricky shapes |

| A360 | Industrial and high-performance components | Flows well, stands up to pressure, does not rust |

| A413 | Hydraulic cylinders, thin-walled parts | Holds pressure well, easy to machine |

These alloys help make parts that are light, strong, and do not rust. Using high pressure die casting with these alloys makes sure car parts are safe, light, and work well for many uses.

Key Automotive Parts Made with Aluminum Die Casting

Engine Components Manufactured Using Aluminum

Aluminum die casting is very important for making engine parts. This process helps make parts that can handle heat and shaking. Some engine parts made this way are:

- Cylinder heads: These shape the area for burning fuel and hold valves and spark plugs.

- Engine blocks: These are the strong base of the engine and help coolant move.

- Intake manifolds and intake tubes: These send air into the engine to help it work better.

- Valve covers and engine control covers: These keep important engine parts safe.

| Aluminum Alloy | Typical Engine Components Manufactured |

|---|---|

| A380 | Crankcases, housings, engine blocks, valve covers, transmission housings |

| A360 | Marine pumps, wet area engine parts (e.g., water pumps) |

| AlSi10Mg | Cylinder heads, turbocharger casings, engine brackets |

| AlSi12 | Sensor mounts, thin-wall cooling system components, small complex parts like cooling junctions and manifolds |

Aluminum die casting makes engine parts light and strong. This helps engines stay cool and last longer. The process lets makers create tricky shapes and exact sizes. Lighter engine parts make cars use less gas and pollute less. Aluminum does not rust, so these parts stay good for a long time.

Aluminum casting helps car makers build engines that are powerful and save energy.

Transmission Parts with Aluminum

Transmission parts need to be tough and exact. Aluminum die casting is often used to make these parts. Some main transmission parts made this way are:

- Transmission cases and housings

- Valve bodies

- Gearbox cases

Aluminum die casting makes transmission parts stiff, light, and the right size. These things help gears shift smoothly and move power well. The process can make thin parts that are still strong. Lighter transmission parts help cars use less gas and make less pollution. Aluminum also helps these parts last longer and work better.

- Aluminum die casting can join many parts into one, saving time and money.

- The process is very exact, so transmission systems stay safe and work well.

Aluminum Structural Die Casting Parts

Structural parts are the main support for a car. Aluminum die casting helps make big, strong, and tricky parts. Some common structural parts made this way are:

- Engine blocks and cylinder heads

- Transmission cases

- Subframes and chassis parts

- Wheels

- Brake components

- Body structural parts like crossmembers and support beams

Aluminum casting gives a good mix of strength and bendiness. These parts help keep people safe in crashes by soaking up energy. Aluminum is light, so cars handle and stop better. It does not rust, so these parts stay strong for many years.

Aluminum die casting lets car makers design parts that are light but still safe in crashes.

Suspension and Brake Parts in Automotive

Suspension and brake systems need parts that are strong and light. Aluminum die casting is used a lot for these parts. Some common suspension and brake parts made this way are:

- Control arms

- Knuckles

- Brackets

- Brake calipers

- Brake housings

Aluminum die cast suspension parts can make cars up to 25% lighter. This helps cars use less gas and handle better. The process makes parts that can take heat and keep their shape. Aluminum helps brakes cool down fast, so they work well even when used a lot.

- Aluminum die casting can make tricky shapes and exact sizes for new suspension designs.

- Strong, rust-free parts help keep cars safe and working well for a long time.

Body and Interior Parts with Aluminum Casting

Aluminum die casting is also used for many body and inside car parts. These parts often need special shapes and smooth surfaces. Some common body and inside parts made this way are:

| Body and Interior Automotive Parts Produced by Aluminum Die Casting |

|---|

| Door shell |

| Roof cover |

| Seat frame |

| Steering wheel cover |

| Dashboard cover |

| Handlebar housing |

- Aluminum handles

- Aluminum brackets

Aluminum die casting can make detailed parts in one step. The process uses high pressure to fill molds and make exact parts. This helps make lots of parts fast and cuts down on extra work. Light body and inside parts help cars use less gas and make less pollution. Aluminum keeps these parts looking good and working well for a long time.

Aluminum casting in body and inside parts helps cars look nice, stay strong, and save energy.

Aluminum die casting is changing how cars are made. Car makers use it to help cars use less gas. It also makes cars safer and last longer. New alloys and machines help make cars lighter. Lighter cars use less fuel and are better for the planet.

The car industry will grow because electric cars are popular. People want cars that use less gas and help the environment.

FAQ

What makes aluminum die casting popular in car manufacturing?

Aluminum die casting makes parts that are strong and light. These parts help cars use less gas and last longer. Car makers like this process because it is fast and very exact.

Can aluminum die cast parts be recycled?

Yes, you can recycle aluminum die cast parts. Recycling uses less energy and saves materials. Many car makers use recycled aluminum to make new car parts.

Which car parts benefit most from aluminum die casting?

- Engine blocks

- Transmission housings

- Suspension arms

These parts must be strong, light, and shaped just right. Aluminum die casting is a good way to make them.