Your Trusted Partner for Custom Die-Casting

HPDC Die Casting

At MORELUX, we specialize in High Pressure Die Casting (HPDC), delivering custom solutions that combine precision, strength, and efficiency. This pressure ensures the metal fills every intricate cavity of the mold, resulting in parts with excellent surface finish, dimensional accuracy, and mechanical properties. With more than two decades of expertise, we help global clients achieve reliable performance in industries where quality matters most. From automotive components to consumer electronics, our high pressure die casting solutions set a benchmark in accuracy and durability.

What is HPDC Die Casting

High Pressure Die Casting (HPDC) is an advanced manufacturing process used to produce precise and complex metal parts rapidly. It involves injecting molten metal into a steel mold cavity under very high pressure. Once the metal solidifies, the mold is opened and a precise, detailed component is ejected.

Unlike sand casting or gravity casting, HPDC allows for mass production of complex shapes with tight tolerances. It also produces parts with a smooth surface finish, reducing the need for secondary machining.

At MORELUX, we understand the importance of consistency. Our HPDC technology allows customers to manufacture parts in large volumes while maintaining dimensional accuracy and excellent surface quality.

High Pressure die Casting Process

The HPDC process consists of several precise stages, from mold preparation to final product ejection and post-processing.

Understanding these stages helps ensure consistent quality and optimized production.

Mold Preparation

The process starts with mold preparation. Before injection, the die mold must be cleaned, lubricated, and preheated. Cleaning removes debris and ensures a defect-free cavity. Lubrication helps in controlling the temperature and allows easy ejection of the casting later.

At MORELUX, we use automated mold preparation systems to maximize efficiency. We ensure proper preheating to reduce thermal shock and prevent cold laps or incomplete filling.

Molten Metal Injection

Once the mold is ready, molten metal—such as aluminum, zinc, or copper alloy—is injected into the cavity at extremely high speed and pressure. The injection pressure can range from 10,000 to over 30,000 psi, rapidly forcing the metal to fill the entire mold. This stage is the heart of HPDC.

The high pressure ensures that the molten metal fills every detail of the mold, even the thinnest walls or smallest corners. By maintaining strict control over temperature and injection velocity, MORELUX guarantees defect-free filling and excellent dimensional accuracy.

Solidification

After injection, the molten metal quickly cools and solidifies. This step is crucial to define the strength and final properties of the casting. The steel mold acts as a heat sink, drawing heat away quickly, which allows for fast cycle times. Rapid cooling under pressure leads to fine grain structure, higher density, and improved mechanical strength.

At MORELUX, we employ advanced cooling systems integrated into the molds. These systems reduce cycle time and ensure consistent solidification, giving our clients stronger and more reliable components.

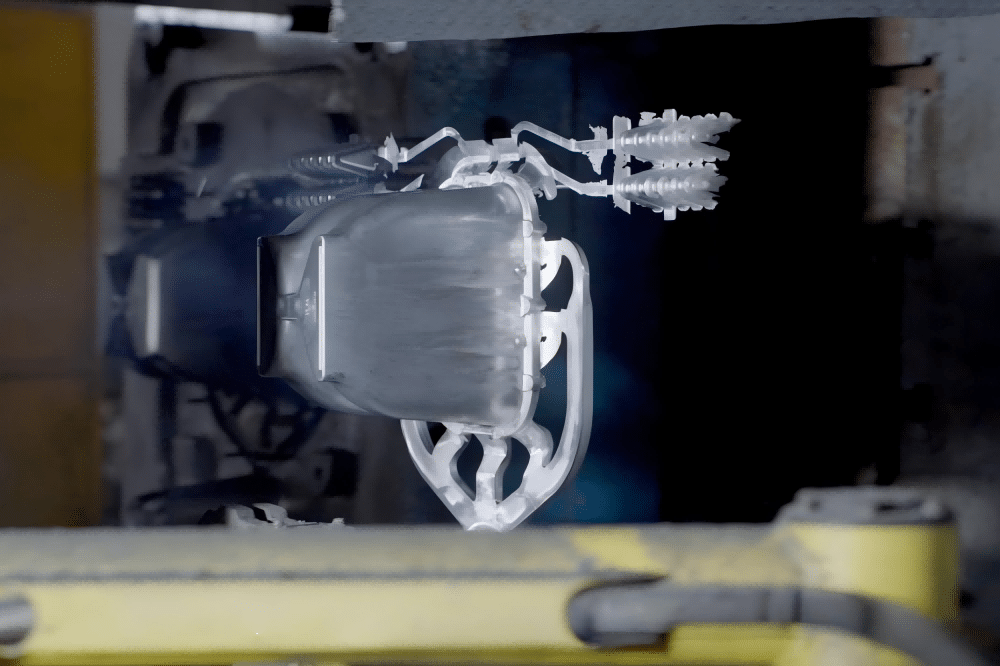

Ejection and Post-Processing

When the metal solidifies, the mold opens, and the casting is ejected. Post-processing follows, which may include trimming excess material, surface finishing, machining, or heat treatment.

MORELUX offers complete end-to-end services, from die casting to CNC machining, anodizing, powder coating, and assembly. This one-stop approach reduces lead time and provides customers with ready-to-use parts.

Advantages and Disadvantages of HPDC Die Casting

Advantages:

- High dimensional accuracy and repeatability

- Smooth surface finish requiring less machining

- Suitable for thin-walled and complex shapes

- High production efficiency for large volumes

- Strong mechanical properties due to rapid solidification

Disadvantages:

- Higher tooling cost compared to sand casting

- Limited to non-ferrous alloys like aluminum, zinc

- Less suitable for small production runs due to mold cost

- Possible issues like porosity if not properly controlled

- Size constraints depending on machine tonnage and mold

Materials Compatible with High Pressure Die Casting

HPDC is compatible with several non-ferrous alloys. Each material brings unique properties, making it suitable for specific applications.

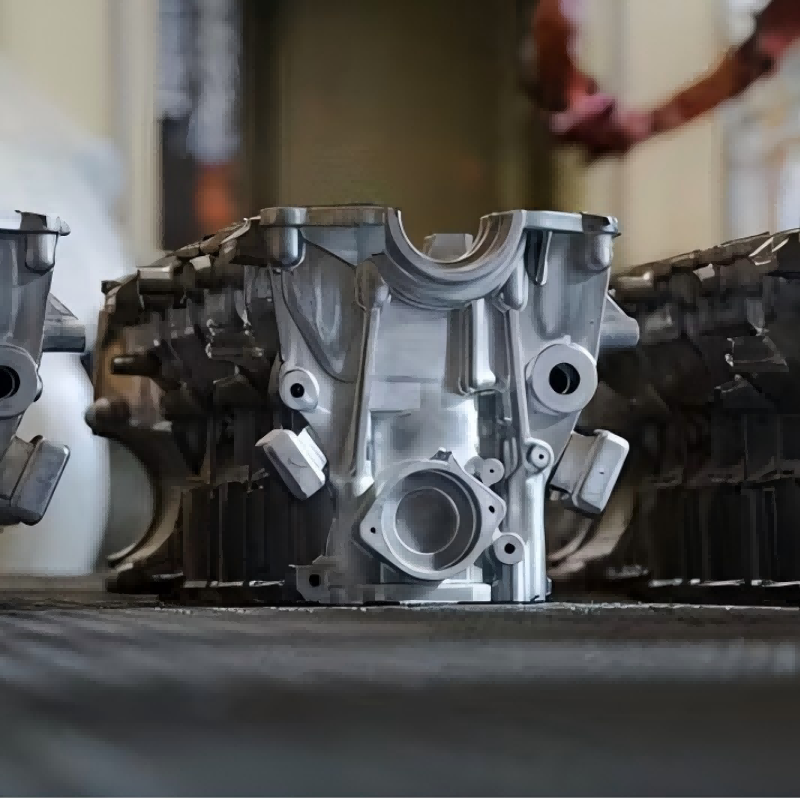

High Pressure Aluminum Die Casting

Aluminum is the most widely used metal in HPDC. It is lightweight yet strong, corrosion-resistant, and ideal for automotive and aerospace applications. At MORELUX, we supply high-strength aluminum die castings for parts such as engine blocks, housings, brackets, and electronic enclosures. Our expertise ensures superior mechanical properties and excellent heat dissipation.

High Pressure Zinc Die Casting

Zinc offers excellent castability, high strength, and superior surface finish. It also supports very thin walls and intricate details. MORELUX provides precision zinc die castings for consumer electronics, locks, gears, and decorative hardware. Our zinc castings stand out for their smooth finish and durability.

Copper Based Alloys Die Casting

Copper-based alloys like brass and bronze provide high wear resistance and excellent thermal and electrical conductivity. We manufacture copper alloy castings for plumbing fittings, electrical components, and industrial applications. These parts combine strength with excellent functional performance.

Common Defects and Quality Control in HPDC Die Casting

Despite its advantages, HPDC can sometimes produce defects that affect product quality. Common defects include:

- Porosity: Gas bubbles trapped inside casting

- Cold shuts: Incomplete fusion lines due to early solidification

- Shrinkage cavities: Voids formed during solidification shrinkage

- Misruns: Incomplete filling of mold cavity

- Surface defects: Flash, roughness, or cracks from improper mold design or metal temperature

Controlling these defects is essential to guarantee part performance. At MORELUX, quality control is integrated at every stage:

- Simulation software to predict filling patterns and prevent defects

- X-ray inspection to detect internal porosity

- CMM measurement to verify dimensional accuracy

- Automated vision systems for surface defect detection

Our quality management system ensures that every batch meets international standards such as ISO 9001 and IATF 16949, giving customers confidence in the reliability of our castings.

Industries and Applications of HPDC Die Casting

HPDC is widely applied across many industries due to its speed, precision, and cost-effectiveness. At MORELUX, we partner with leading global brands in these industries, offering tailored solutions that meet performance, cost, and production requirements. Some key applications include:

- Automotive: Engine blocks, transmission housings, brackets, heat sinks

- Aerospace: Lightweight structural components, housings, connectors

- Electronics: Enclosures, heat sinks, connectors, mobile device parts

- Medical Devices: Precision housings, brackets, components requiring high accuracy

- Consumer Goods: Decorative hardware, appliance parts, furniture fittings

- Industrial Equipment: Pump housings, valves, machinery components

- Lighting and Electrical: Switch parts, connectors, and terminals

MORELUX:

Top HPDC Die Casting

Manufacturer & Supplier

At MORELUX, HPDC is more than just a process—it is our core expertise. With advanced equipment, experienced engineers, and strict quality control, we deliver high-performance die castings that support industries worldwide.

Whether you need lightweight automotive parts, precision electronics housings, or durable industrial components, MORELUX provides tailored high pressure die casting solutions. Our commitment to innovation, reliability, and customer satisfaction makes us a trusted partner in your success.

20+ Years of Casting Experience

With over two decades in the die casting industry, we bring deep knowledge of alloys, mold design, and process control. This experience ensures we solve complex challenges and deliver consistent results.

30+ Designers & Engineers

Our team of over thirty professional designers and engineers provides custom solutions for every client. From concept to final product, we ensure that design, tooling, and production meet your specific needs.

Max ton 2,000T Die Cast Machine

We operate advanced die casting machines ranging from 180T to 2,000T. This capacity allows us to produce both small precision components and large structural castings.

50+ Million USD Annual sales

Our global customers trust MORELUX for quality and scale. With over 50 million USD in annual sales, we have proven capacity to handle large orders while ensuring delivery reliability.

Comparison of HPDC with Other Casting Methods

Understanding how HPDC compares with other casting techniques can help you select the most suitable process for your needs.

Squeeze Casting VS High Pressure Die Casting

Squeeze Casting: Combines casting and forging by applying static pressure during solidification, resulting in near-net shape parts with minimal porosity.

HPDC: Injects molten metal at high velocity and pressure into the mold; faster and suited for thin-wall, detailed parts.

Squeeze casting is chosen when higher mechanical properties and minimal defects are required, but HPDC excels in high throughput and fine detail.

High Pressure Die Casting VS Low Pressure Die Casting

HPDC: Uses extremely high pressure to inject molten metal quickly into a closed mold, ideal for high-volume production of complex parts.

Low Pressure Die Casting: Uses lower pressure to fill molds from the bottom, reducing turbulence. It is suitable for larger, less detailed parts but with slower cycle times.

HPDC offers faster cycle speeds and better surface finish, while low pressure casting is often preferred for thicker, heavier components.

How Do Cold‑chamber and Hot‑chamber HPDC Differ in Cycle Speed

Hot-Chamber HPDC: The injection mechanism is immersed in molten metal, allowing faster cycles and is typically used for low melting point metals like zinc and magnesium.

Cold-Chamber HPDC: Molten metal is ladled into a separate injection chamber for each shot, making the cycle slower but allowing higher melting point alloys like aluminum and copper.

MORELUX utilizes both technologies depending on material and part complexity, optimizing speed and quality for each project.