Patient safety depends on biocompatibility in medical die-castings. Makers must pick safe materials and use special surface treatments. This helps devices work well and follow the rules. Rules are getting more complex, and this causes problems like:

- Checking the chemicals in materials (a strict requirement for all materials, including copper die-casting alloys) and how they are made.

- Looking at risks in finished medical devices after cleaning.

- Careful tests for dangerous substances and clear supply chain records.

Medical device makers have problems with lab results that do not match, changing rules, and needing expert advice on toxicology, especially when applying surface treatments to materials like aluminum die-casting.

Key Takeaways

- Biocompatibility means using safe materials in medical devices. These materials do not hurt the body. Medical die casting uses strong metals like aluminum, stainless steel, and zinc alloys. These metals make device parts that are exact and last a long time. Special surface treatments like anodizing and coatings help protect devices from rust. These treatments also make devices safer and help them last longer. Following strict rules from ISO 10993 and the FDA keeps medical devices safe. These rules help protect patients. Careful design, testing, and quality control are important for materials and surface finishes. These steps lower risks and help devices work better.

Biocompatibility in Medical Die Casting

What Is Biocompatibility?

Biocompatibility means a material can be used in the body safely. It should not hurt people or cause bad reactions. Groups like ISO 10993 set rules for biocompatibility. They say a material must work well with the body in its job. When a material is used in medical die casting, it should not make tissues or organs react badly. To test this, experts look for chemicals that might come out of the material. They also watch how the body acts after a device is put in. A safe material will only make a thin layer form around it, with little swelling. Medical die casting uses these ideas to pick and test metals and alloys for devices that touch the body.

Why It Matters for Medical Devices

Medical die casting helps make strong and safe devices for patients. If materials are not biocompatible, they can cause health problems. People might get rashes, swelling, or even cell damage. Sometimes, blood clots or narrow blood vessels can happen. Unsafe materials may rust, be hard to clean, or lose their cleanliness. Even tiny amounts of bad substances can be dangerous. For example, some hip implants let out metal ions, which caused swelling and made the device fail. Some glues in wearable devices have caused allergies and made companies recall products. These problems show why biocompatibility is very important in medical die casting. Makers must pick good materials and use safe steps to keep patients safe and make sure devices work right.

Medical Die Casting Processes and Applications

Applications of Medical Die Casting in Healthcare Devices

Die casting is important for making many medical device parts. Makers use it to build strong and exact pieces for many healthcare tools. Some common uses are:

- Surgical instruments like forceps, scalpels, and retractors need to be light and easy to clean.

- Parts for diagnostic machines, such as X-ray tube covers and MRI parts.

- Implantable devices, like orthopedic screws, joint replacements, and dental implants, are often made from titanium or aluminum alloys because they are safe for the body and do not rust.

- Medical tools like forceps, tweezers, and scissors must have the right shape and size.

- Key parts for hospital beds, monitors, oxygen pumps, peristaltic pumps, and insulin pumps.

- Pieces for machines that check patients, CT scanners, and breathing machines like oxygen concentrators.

- Optical parts for endoscopes and microscopes.

Makers pick materials like aluminum, magnesium, zinc, copper, titanium, and stainless steel alloys. These are strong, last a long time, and work well with the human body. These materials help medical parts stay safe and work as they should.

Advantages of Die Casting in Medical Device Manufacturing

Die casting has many good points for making medical devices. This method lets makers create very exact and smooth parts. It is important for parts that must fit just right. Makers can also make tricky shapes that other ways cannot do.

Die casting is good for making lots of parts at once. It costs more to start, but each part gets cheaper when you make more. This way also wastes less material than cutting parts out.

Makers like die casting because it makes the same part over and over. Using machines helps make things faster and better. Makers can use many safe materials, like aluminum and stainless steel alloys, so die casting is a top pick for medical tools. When making many parts, die casting saves money, but cutting parts is better for small jobs.

Tip: Picking die casting for medical devices helps companies make safe, good parts. It also keeps costs down and follows the rules.

Biocompatible Materials Used in Medical Die Casting: Types, Properties, and Selection Criteria

Aluminum Alloys

Aluminum alloys are used a lot in medical die casting. They are light, strong, and do not rust easily. Makers use them for tools, frames, and covers. The table below lists some main aluminum alloys and what they do:

| Alloy | Alloy System | Key Properties | Typical Applications in Medical or Related Fields |

|---|---|---|---|

| A356 | Al-Si | Good strength, ductility, machinability, moderate corrosion resistance | Medical equipment housings, brackets |

| A380 | Al-Si | Excellent fluidity, pressure tightness, moderate strength | Components needing corrosion resistance and castability |

| B390 | Al-Cu | Very high strength and hardness, moderate ductility | High-strength parts (less common in direct medical use) |

| C355 | Al-Cu | Good strength, corrosion resistance, ductility | Structural components needing corrosion resistance |

| AM6061 | Al-Mg | Good strength, ductility, corrosion resistance | Structural parts, device frames |

| K-Alloy | Al-Si-Cu-Mg | Exceptional corrosion resistance, high strength | Devices for harsh environments |

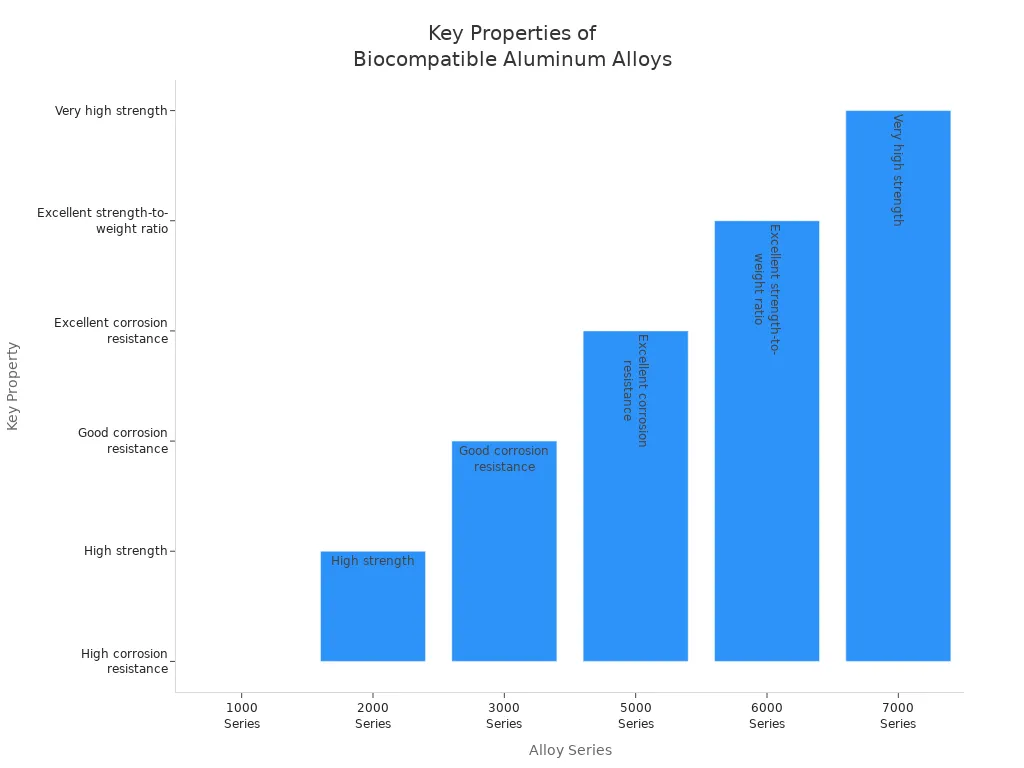

Parts made from these alloys are safe and last a long time. The chart below shows the main features of big aluminum alloy groups used in medical die casting:

Note: Aluminum alloys like 6061 and 7075 are picked for implants and tools. They are strong, do not rust, and are easy to clean.

Stainless Steel

Stainless steel is also a top pick for medical die casting. It makes a layer that keeps it from rusting or getting damaged by chemicals. This layer helps it stay safe in tough places. Some important things about stainless steel are:

- It does not need thick coatings to stop rust.

- Its smooth surface makes it easy to clean and sterilize.

- Makers use it for tools, implants, and frames because it is strong.

- Stainless steel works well for a long time where safety and cleaning are important.

Zinc Alloys

Zinc alloys are important in medical die casting too. They have special uses in new medical devices. When picking zinc alloys, makers want:

- Safety for patients who touch the device.

- Hardness and shape stability for strong, exact parts.

- Germ-fighting power to lower infection risk after cleaning.

- Ability to make tiny, detailed shapes for tricky parts.

- Shielding to keep electronics safe from outside signals.

- Strength and rust resistance for long-lasting parts.

- Fit with tight size rules for devices that must work right.

Designers use zinc alloys for small, detailed parts and cases for electronics. These safe materials help meet tough rules for health and how well devices work.

Regulatory Standards for Biocompatibility

ISO 10993

ISO 10993 gives the main rules for biocompatibility in medical die casting. These rules help makers check if materials are safe for the body. ISO 10993 says makers must use risk management to test materials. They need to:

- Test how safe the material is using risk management.

- Sort devices by how and how long they touch the body.

- Look at all the data they can find.

- Find missing information by checking risks.

- Decide if they need more data for safety.

- Check the device’s safety very carefully.

- Use these steps for devices that touch the body, even inside.

- Think about dangers if the device changes or breaks.

- Test the finished device, how it is made, and how it is cleaned.

- Use risk to pick what tests are needed, following agreed rules.

ISO 10993 says cytotoxicity testing is very important. This test checks if the material hurts cells. Makers also need to think about what happens if the device changes or breaks and new parts touch the body.

FDA Guidelines

FDA guidelines work with ISO 10993 to make sure devices are safe. The FDA wants makers to check the device’s materials, chemicals, and how it is made. They also need to look for chemicals that could leak out or form when the device breaks down. The FDA uses risk management and looks at how the device touches the body.

Tests must follow Good Laboratory Practice rules. Makers must give full test results or use trusted rules for the FDA to check. If anything changes, the FDA wants the device tested again. The FDA also wants makers to think about what happens if the device fails and how that could hurt people. The FDA has a list of tests, like cytotoxicity, irritation, and systemic toxicity. Chemistry tests help find and measure materials and things that can leak out. The FDA says to use special guides or agreed rules to make reviews faster.

Compliance for Surface Finishes

Surface finishes are important for meeting biocompatibility rules. Makers must make sure coatings and treatments do not add anything harmful. Both the FDA and ISO 10993 say to test finished surfaces for cytotoxicity and other dangers. Good quality in surface finishes helps keep patients safe and stops devices from failing. Makers should not use unsafe treatments and should clean and sterilize devices the right way. Meeting these rules for surface finishes helps make medical devices safer and more dependable.

Note: Following ISO 10993 and FDA rules for surface finishes helps devices meet world safety standards and keeps patients safe.

Advanced Surface Modification Techniques for Enhancing Biocompatibility in Medical Die Cast Parts

Modern medical devices need special surface changes to work better. These changes help parts last longer and keep patients safe. They also stop rust and make parts stronger. Each method helps medical die casting parts in its own way.

Anodizing

Anodizing is a common way to change the surface of metals like titanium and aluminum. This process makes a hard layer on the outside. The layer keeps the part from rusting and makes it tougher. Makers use anodizing to make devices safer and more dependable. The new surface lowers the chance of bad reactions in the body. Recent studies show anodizing helps devices last longer and work better. The hard layer also makes cleaning and sterilizing easier, which keeps patients safe.

Parylene Coating

Parylene coating puts a thin, even layer on parts using a special vapor. This layer is thick and keeps water out. It stops rust and keeps fluids away from the metal. For example, magnesium alloy stents with parylene C do not rust for six months. The coating stays strong even if the part bends or stretches. Parylene C is safe for the body and works with other coatings for medicine. These things make parylene coating a great choice for stopping rust and making devices safer.

E-Coating and Chem Film

E-coating covers parts with a smooth, even layer using electricity. This method works well for parts with tricky shapes. E-coating helps stop rust and keeps the surface smooth. Chem film, or chromate conversion coating, makes a thin, safe layer on metals like aluminum and zinc. This layer stops rust and gets the part ready for more coatings or paint. Both methods help devices meet safety rules by lowering bad reactions and making them last longer.

PVD and Biochrome

Physical Vapor Deposition, or PVD, puts a thin, tough layer on parts. It uses metal vapor to make the surface hard and smooth. PVD makes parts harder, lowers friction, and stops rust. Biochrome is a chromium-based coating that does the same things. It gives a shiny, smooth surface that does not rust and is easy to clean. Both PVD and biochrome help devices last longer and stay safe for patients. These coatings also let makers use new materials in medical tools.

Functionally Graded Coatings

Functionally graded coatings are a new way to treat surfaces. These coatings change from one layer to another inside the part. Additive manufacturing, like Selective Laser Melting, helps control these changes. Some big improvements are:

- Additive manufacturing makes implants with different holes, mixes, and structures.

- Graded materials fix problems like stress and loose implants by helping the device stick to bone.

- Old coatings only work for small parts, but new ways let makers build bigger, complex shapes.

- Graded holes help bone grow and hold the device tight.

- Devices with these coatings are stronger and work better in the body, so they last longer.

- There are still some cost and safety problems, but the good points are clear.

- These ideas work for many medical die cast parts, not just bone implants.

Functionally graded coatings help devices fit the body’s needs, making them safer and better.

Ion Implantation and Carbon Doping

Ion implantation and carbon doping use high-tech ways to change the surface of alloys. Ion implantation adds atoms like nitrogen or carbon to the top layer. This makes the surface harder and stops rust and wear. Carbon ion implantation makes the surface even tougher, while nitrogen helps stop wear. These treatments only change the outside, so the inside stays the same. Studies show these methods make titanium, magnesium, and stainless steel last longer. They also keep the surface safe for human cells, which is very important. Unlike some other ways, these do not cause bad reactions in the body.

Tip: Makers should pick surface changes based on how the device will be used, how tough it needs to be, and what the rules say. Each method has its own good points for making devices safer and better.

Comparing Cost-Effectiveness and Scalability

Surface changes can cost different amounts and work for different sizes of jobs. Some, like e-coating and anodizing, are good for making lots of parts and do not cost too much. Others, like ion implantation and functionally graded coatings, give more benefits but cost more and need special tools. The medical device industry is trying to make these ways cheaper and easier for big jobs. As technology gets better, more devices will use these strong surface changes.

Surface Finish Best Practices

Avoiding Non-Compliant Treatments

Medical device makers must not use unsafe surface treatments. Some finishes can cause problems like cytotoxicity or allergies. For example, if anodizing is not sealed or rinsed well, it can leave bad chemicals. Paints with too many volatile organic compounds (VOCs) or colors not approved by the FDA may irritate skin. Nickel or chromium plating, if not covered right, can make devices unsafe.

The table below shows good ways and things to avoid for safe surface finishing:

| Best Practice Aspect | Details |

|---|---|

| Compliant Surface Finishes | Sealed anodizing (Type II & III), FDA-approved powder coatings, electropolishing, medical-grade painting with low-VOC formulations |

| Surface Finish Restrictions | Avoid unsealed anodizing, paints with VOCs, non-FDA pigments, nickel/chromium plating without encapsulation |

| Quality Control | Use validated protocols and certified suppliers |

| Application Examples | Surgical enclosures, instrument casings, diagnostic equipment |

Tip: Always pick surface finishes that follow world biocompatibility rules. This keeps patients safe and helps meet the law.

Ensuring Consistent Quality

Keeping the surface quality the same makes devices safer and better. Makers use many checks to reach this goal. They design and care for dies to keep metal flowing evenly and stop mistakes. Picking the right materials is important, because pure alloys have fewer problems. After casting, steps like deburring, grinding, and polishing help make the finish even.

- Grinding uses rough tools to make surfaces smooth and exact.

- Polishing gives a shiny look and helps parts move easily.

- Deburring takes away sharp edges so parts are safe to touch.

- Shot blasting cleans and roughens surfaces so coatings stick better.

Makers also watch things like pressure and mold heat to stop mistakes. They follow rules like ISO 1302 and ASTM B633 for how rough or smooth surfaces should be. These steps help all medical die cast parts have good finishes.

Note: Using set steps and testing often makes sure every device is safe and high quality.

How Biocompatibility and Surface Treatments Impact the Safety and Reliability of Medical Devices

Minimizing Patient Risk

Biocompatibility is very important for patient safety with medical devices. When makers pick materials and surface treatments that pass hard tests, they lower the chance of bad reactions. Studies show special coatings, like iridium oxide and diamond-like carbon, help stop blood clots and swelling. These coatings help people heal faster and make devices less likely to fail.

- Bioactive coatings help the body accept implants. They help the device stay in place and lower swelling.

- Surface changes, like ion implantation and laser nano-texturing, make surfaces that fight germs. These surfaces lower infection risk and help bone and tissue grow around the device.

- Antimicrobial coatings, such as TridAnt, kill germs fast and stop biofilm from growing. This helps stop infections.

- Immuno-compatible coatings, like IntimateBond Osteoblast, help bone cells grow and stop unwanted tissue, making the device safer.

Testing for biocompatibility makes sure each device is safe before people use it. By using these new treatments and careful testing, makers can lower patient risk a lot.

Note: Devices with good biocompatibility and special surface treatments have fewer infections, less swelling, and fewer failures in labs and real life.

Enhancing Device Performance and Longevity

Surface treatments do more than keep patients safe. They also help medical devices last longer and work better. Research shows changing surfaces on titanium and other alloys makes them harder and stops rust. This means devices can handle tough conditions inside the body.

- Plasma immersion ion implantation puts metal ions on the surface. This makes the device harder and less likely to wear out.

- Sol-gel and ceramic coatings stop rust and keep metal ions from leaking, which lowers rejection.

- Micro-arc oxidation makes a strong ceramic layer that protects the device from body fluids and movement.

- Composite coatings with copper or manganese keep devices safe and fight germs, helping them last longer.

Tests show these treatments keep devices strong and safe for a long time. New surface changes, like Endexo technology, also help stop blood clots and make devices easier to use. They lower friction, reduce harm during use, and help the device work as it should.

Devices with these surface treatments fail less, work better, and last longer, making them a smart pick for patients and healthcare workers.

Using biocompatible materials and new surface treatments makes medical die casting safer. It also helps devices work better and last longer. Recent research shows that each device needs special biomaterial properties. Coatings should help the device work well with body tissues. Makers should do a few important things.

- They need to design molds carefully and watch the process closely to stop mistakes.

- They should test and check quality at every step.

- They must work with experts to pick the best materials and surface changes.

Doing these things helps companies follow the rules. It also helps them create new and better ways to make medical devices.

FAQ

What makes a material biocompatible for medical die casting?

A biocompatible material is safe for the body. It does not cause harm or bad reactions. It does not rust or break down easily. It will not make people have allergies. These materials help the body heal after use. Medical experts check these materials to make sure they are safe.

How do surface treatments improve medical device safety?

Surface treatments put a strong layer on the device. This layer keeps out rust and stops damage. It helps the device last longer and work better. The layer also keeps the device safe for people to use.

Which surface finishes should manufacturers avoid?

Manufacturers should not use unsealed anodizing or paints with lots of VOCs. They should also avoid nickel or chromium plating without a safe cover. These finishes can make people have allergies or not pass safety checks.

Why do regulatory standards matter in medical die casting?

Regulatory standards, like ISO 10993 and FDA rules, set tough safety steps. They make sure every device is safe for health. These rules help protect patients from getting hurt.