Electronics Die Casting

MORELUX: Powering Consumer Electronics with Precision Die Casting

Need reliable components for your cutting-edge devices? MORELUX is your partner. We specialize in precision die casting for the consumer electronics industry.

Our expertise ensures top-tier performance and reliability. We provide custom parts, perfectly tailored to your specifications. From initial concept to final product, we deliver.

MORELUX focuses on quality and innovation. We use advanced techniques and premium materials. Our solutions meet your unique project needs.

Choose MORELUX for your next project. Experience superior precision and efficiency. Contact us today for a consultation.

Advantages of Die Casting for Electronic

- High Precision and Accuracy: We produce parts with tight tolerances and consistent dimensions. This ensures perfect fitting of electronic housings and connectors, reducing extra machining.

- Strong and Durable Components: Using alloys like aluminum and zinc, we create metal parts that are tough and long-lasting. These parts withstand mechanical stress and everyday wear.

- Complex Designs and Thin Walls: Our process can form intricate shapes and thin-walled structures. This supports the trend of making smaller, lightweight electronic devices without losing detail.

- Lightweight Solutions: We specialize in aluminum castings, which provide strength while keeping components light. This is ideal for portable electronics.

- Cost-Effective Mass Production: Though initial tooling can be costly, our die casting process is very efficient for large volumes. It ensures fast production and consistent quality, lowering costs per unit.

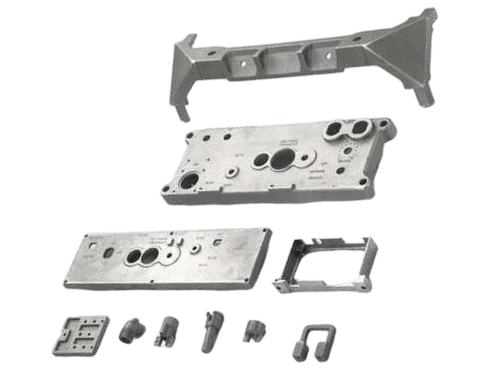

Consumer Electronic Casting

Custom Solution by MORELUX

MORELUX offers a comprehensive die casting solution for the consumer electronics industry. From precise tooling and efficient casting to strict quality control and integrated assembly, our approach delivers superior components ready for modern electronic devices. With advanced technology, experienced engineering teams, and a commitment to excellence, MORELUX supports clients in launching innovative, durable, and high-quality consumer electronics products.

Tooling and Design

MORELUX offers tailored tooling and design services for consumer electronics. We use advanced CAD software to create precise die casting molds. Our team optimizes designs to improve strength and reduce weight. For example, we have reduced mold cycle times by 15% in recent projects. We use high-grade steel for durability, allowing the mold to last for over 500,000 casting cycles. We typically create molds with a tolerance of ±0.02 mm to guarantee accuracy. Our tooling can handle complex geometries, ensuring high accuracy and consistency in consumer electronics parts.

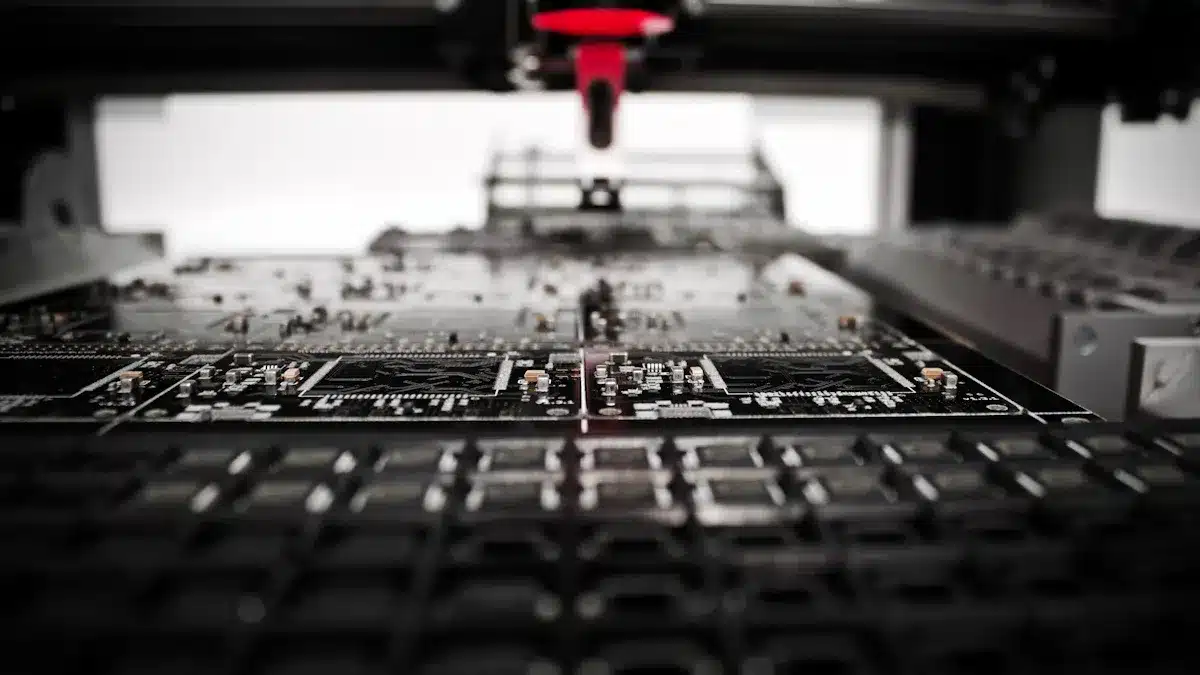

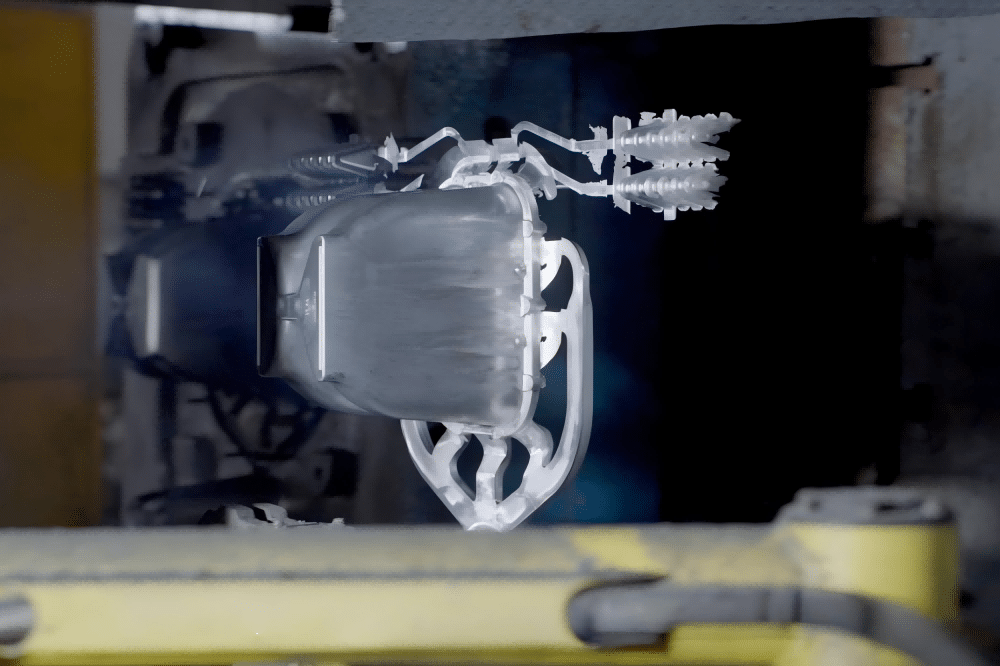

Die Casting Capabilities

MORELUX offers various die casting methods for electronics parts, including high-pressure, low-pressure, and gravity die casting. We operate state-of-the-art high-pressure die casting machines with clamping forces ranging from 280 to 2000 tons. This allows us to produce fine, intricate components with wall thicknesses as low as 0.5mm. Our flexible casting processes allow us to produce everything from tiny connectors to larger housings with complex features. Our monthly capacity exceeds 200,000 units, meeting the high volume demands of consumer electronics manufacturers.

Quality Control and Testing

MORELUX have strict quality control procedures at every step of production. Incoming materials are inspected for purity and composition. During casting, we monitor temperature and pressure carefully. MORELUX enforces stringent quality checks using CMM (coordinate measuring machines) and X-ray inspection systems. Electrical conductivity tests ensure parts meet electronic standards. We maintain a defect rate below 0.2%. Our team performs mechanical and thermal testing to ensure parts meet durability standards and operate reliably in consumer electronic devices.

Assembly & Integration

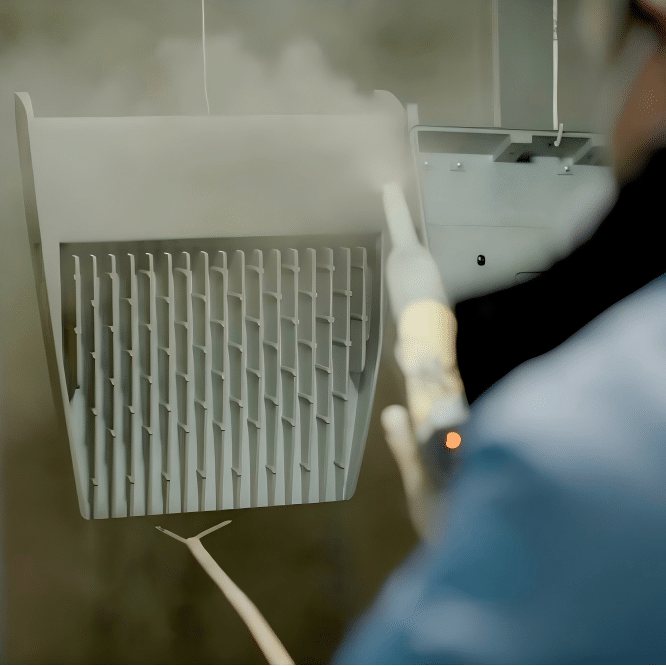

We provide turnkey assembly solutions including surface finishing, press fitting, and electronic component integration. After casting, parts undergo finishing processes such as machining, polishing, and anodizing to improve surface quality and corrosion resistance. Our cleanroom facilities support ESD-sensitive assembly. MORELUX’s integrated approach reduces lead times by 20%, streamlining the production cycle for consumer electronics products. This versatility helps meet the unique needs of different electronic devices and applications.

Metals Used in Consumer Electronics Die Casting

At MORELUX, we provide die casting solutions using zinc, aluminum, and copper alloys for consumer electronics. Zinc is perfect for small, detailed parts needing precision and a smooth finish. Aluminum offers light weight, strength, and excellent heat dissipation, ideal for structural components. Copper alloys, though less common, are used where high conductivity and durability are essential, such as connectors and heat exchangers. Our expertise ensures the right metal is chosen to meet your product’s performance and quality needs.

Electronics Aluminum Alloy Die Casting

At MORELUX, we specialize in aluminum die casting services for consumer electronics using several key aluminum alloys, each offering unique benefits tailored to industry needs. These aluminum alloys ensure that MORELUX delivers durable, lightweight, and high-performance parts for consumer electronics, meeting the demands for strength, precision, and thermal management.

- A380 aluminum alloy is our most commonly used material. It features excellent fluidity and casting ability, making it ideal for creating lightweight, strong parts. With a tensile strength of up to 330 MPa, A380 is widely used in smartphone and tablet housings, laptop frames, and heat sinks where strength and heat dissipation are crucial.

- A356 aluminum alloy provides a good balance of strength and castability, with a tensile strength around 310 MPa. It is suitable for durable electronic casings, frames, and brackets that face high mechanical stress in daily use.

- 356-T6 aluminum alloy is a heat-treated form of A356. Its enhanced mechanical properties and yield strength of 240 MPa make it perfect for structural components like laptop frames and tablet covers, combining durability with lightness.

- A360 features high corrosion resistance and is used in parts exposed to harsher environments or requiring pressure tightness. It’s valued for its strength at elevated temperatures and good fluidity for thin-walled and intricate parts.

Electronic Zinc Alloy Die Casting

At MORELUX, we specialize in zinc alloy die casting services for consumer electronics. We use several typical materials, each chosen for its unique properties and suitability for different applications.

- Zamak 3 is our most common alloy in North America. It has excellent mechanical strength, great castability, and high fluidity. These features make it ideal for complex electronic parts that require good strength and a smooth surface finish.

- For the European market, we often use Zamak 5. It shares similar mechanical properties with Zamak 3 but offers better corrosion resistance. This makes it perfect for precision die-cast parts in consumer electronics that need durability.

- Zamak 7 is a high-purity version of Zamak 3 with lower magnesium content. It has improved fluidity and ductility, providing a finer surface finish. It is favored for high-quality electronics where detailed and smooth parts are critical.

- We also use ZA-8, a zinc-aluminum alloy with about 8.4% aluminum. It is the only ZA alloy suitable for hot-chamber die casting and offers higher strength and creep resistance. ZA-8 is great for parts that must withstand heavy loads and long-term use.

- Finally, our EZAC alloy has superior creep resistance, yield strength, and hardness. It is ideal for consumer electronic parts requiring enhanced mechanical performance and durability.

Copper Alloy Die Castings for Electronics

From MORELUX’s perspective, we provide copper die-casting services for consumer electronics using several key copper alloys. The most common materials are brass, bronze, and beryllium copper, including specific grades such as Copper Alloy C87500 (Copper Silicon), C83600, and C92200. Pure copper, while highly conductive, tends to crack, shrink, and become porous during die casting; therefore, these alloys are chosen for their enhanced mechanical strength, corrosion resistance, hardness, and excellent electrical conductivity, which are critical for electronic components.

- Brass is widely used for electrical connectors because it offers good conductivity and easy machinability. Typical grades like CW508L and C26000 ensure reliable performance in connectors and terminals. Bronze provides superior wear resistance, making it suitable for mechanical parts within electronic devices where durability is essential.

- Copper Alloy C87500 (Si Brass) stands out for its excellent strength and electrical conductivity. It is ideal for connectors and terminals requiring both durability and reliable electrical performance. Beryllium copper is employed for high-strength electrical contacts, connectors, and springs. Its aerospace-grade properties deliver superior mechanical and electrical performance in demanding applications.

Available Surface Finishes

For Consumer Die Casting

For die-cast electronic components, a high-quality surface finish is essential not only to meet aesthetic and commercial demands but also to ensure functional integrity, long-term durability, and compatibility with additional manufacturing processes that preserve product quality and user experience.

MORELUX capabilities extend from mold design to advanced surface treatments tailored to enhance both the aesthetics and durability of electronic device parts.

- Clear Coating

- Anodizing

- Transparency

- Sanding & Polishing

- Spray painting

- Bead Blasting

- Tinting/Dyeing

- Electroplating

- Insert Installation

- Chrome-coating

- Powder Coating

- Passivation

Precision Die Casting Consumer Electronics Components

Device Enclosures

We manufactures durable and lightweight enclosures for smartphones, smart home devices, and wearables. These parts protect internal electronics while allowing sleek and modern designs. Our precision casting ensures tight tolerances.

Heat Sinks to Dissipate Device Heat

Electronic devices generate heat during operation. MORELUX’s heat sinks are precisely cast to maximize heat dissipation. This helps prevent overheating and extends the device’s lifespan, especially in high-performance gadgets.

Structural Chassis and Frames

The internal chassis and frames support components and maintain device integrity. MORELUX produces strong and stable structures that withstand daily use and shocks. This ensures reliable performance in rugged or portable electronics.

Connectors and Electrical Interface Parts

We produce connectors, terminal blocks, and other electrical interface components. These parts require precise shapes and conductivity standards to ensure secure and efficient electrical connections in consumer electronics.