Aluminum die-casting is transforming the way telecommunication infrastructure is built. It delivers precise, durable, and efficient solutions for modern networks. Reports indicate a rising demand for telecom die-castings components that meet strict industry standards, especially as 5G and IoT technologies accelerate growth. In 2024, the market was valued at USD 2.5 billion and is projected to reach USD 4.1 billion by 2033. This expansion is driven by lightweight, heat-dissipating enclosures (a similar functional requirement seen in high-efficiency lighting die-castings) and the need for robust infrastructure. Telecom operators are now prioritizing network reliability, sustainability, and seamless connectivity by leveraging the advantages of these innovative die-casting techniques. Automation, advanced alloys, and eco-friendly processes are setting new benchmarks for the telecommunication sector.

Key Takeaways

- Aluminum die casting makes parts that are strong and light. These parts do not rust. They help build good telecom networks. This is important for 5G and IoT.

- New ways like high-pressure and vacuum casting make better parts. They also make parts faster. This helps meet the hard needs of telecom.

- Smart manufacturing uses IoT sensors and machines. This cuts down on mistakes. It saves energy. It makes sure telecom parts are always good.

- Using recycled aluminum and green ways saves money. It also lowers carbon footprints. This makes telecom hardware better for the planet.

- Advanced alloys, surface treatments, and 3D printing help a lot. Telecom companies can make strong and exact parts. These parts work well in tough places.

Aluminum Die Casting Telecommunication Trends

The aluminum die-casting industry is changing fast in telecom. More people want 5G, lighter parts, and better processes. This makes companies use new aluminum die casting telecommunication solutions. The table below shows the main trends and reasons for these changes:

| Trend / Driver | Description | Relevance to Telecommunications Sector |

|---|---|---|

| Infrastructure Development & Urbanization | Cities are growing and need strong, rust-proof aluminum parts. | More cell towers and weatherproof boxes for telecom gear. |

| Technological Advancements in Die Casting | New methods like pressure and vacuum die casting make light, tough, and rust-proof parts with cool shapes and smooth surfaces. | Needed for making telecom parts that must last and fit well. |

| 5G Deployment, IoT Expansion, Smart Cities | More 5G, IoT, and smart cities mean more need for special aluminum parts. | More aluminum die cast parts are needed for telecom, especially where governments invest in broadband. |

| Sustainability & Recyclability | Aluminum can be recycled and saves energy, which helps the planet. | Helps make green telecom hardware and meet rules for being eco-friendly. |

| Regional Growth Example: Canada | Canada’s government spends money on broadband and green factories, helping the market grow. | More need for strong aluminum cases and parts, especially for rural 5G and smart cities. |

High-Pressure & Vacuum Casting

High-pressure die-casting and vacuum casting are now very important for telecom gear. High-pressure die casting makes strong, exact, and cheap parts like radio frequency boxes. This method uses high pressure to make parts less porous and stronger. Vacuum casting helps make bigger, thinner, and more detailed parts with few mistakes. These ways give smooth surfaces and keep sizes just right, which is key for 5G base station covers and other telecom uses. High-pressure die-casting is good for making lots of parts fast. Vacuum casting helps tools last longer and makes less waste. These new methods help aluminum die-casting meet the tough needs of today’s telecom systems.

Smart Manufacturing & IoT

Smart die-casting is changing how aluminum die-casting works for telecom. Factories use IoT sensors to watch furnaces and machines all the time. This helps control mold heat, pressure, and metal heat, so there are fewer mistakes and better products. Robots and machines help make things faster and with fewer errors. Smart die-casting finds problems right away and fixes them, which is important for reliable telecom parts. Using IoT and Industry 4.0 also helps save energy and materials, making the process greener.

Sustainability Initiatives

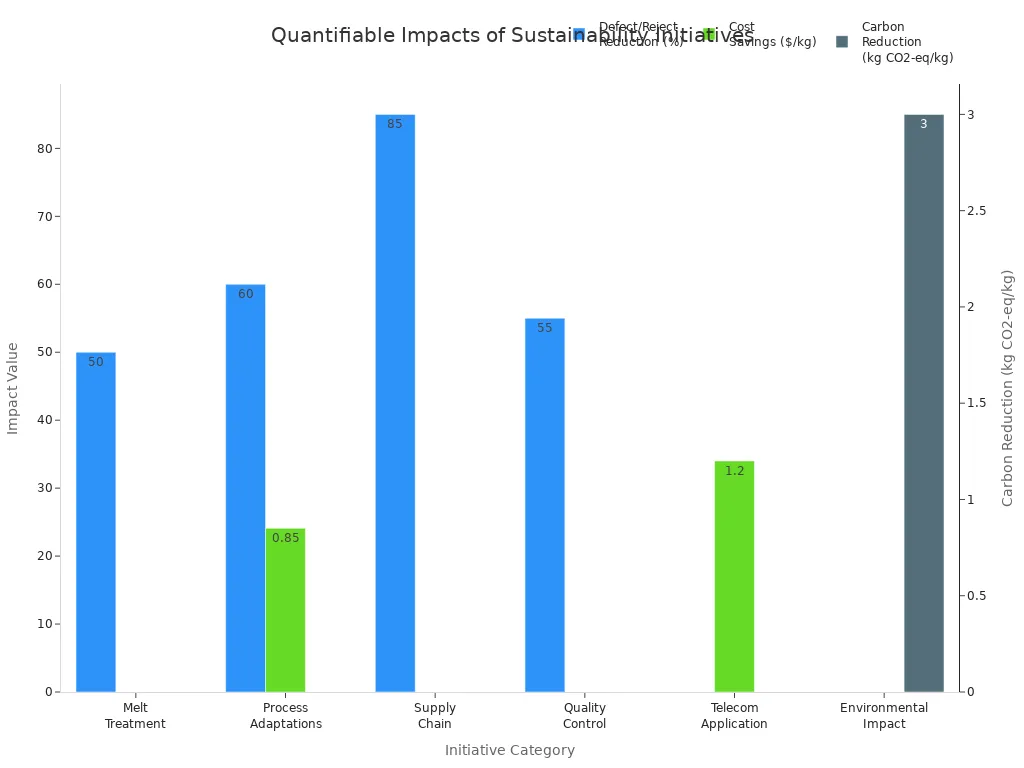

New green ideas are leading aluminum die-casting telecommunication. Companies use recycled aluminum, closed-loop recycling, and save energy to help the environment. The chart below shows how these actions help:

| Initiative Category | Specific Initiative/Example | Quantifiable Impact/Result |

|---|---|---|

| Melt Treatment Technologies | Using ultrasonic rotary degassing, ceramic filters, and electromagnetic stirring | Fewer mistakes by 40-60%; parts get 25-30% stronger |

| Process Adaptations | Vacuum die casting and better shot control | Less porosity by 60-80%; saves about $0.85 per kg |

| Supply Chain Strategies | More sources and closed-loop recycling | Fewer supply problems by 85%; alloy costs drop by 15% |

| Telecom-Specific Application | 5G base station covers with 85% recycled AlSi9Cu3 alloy | Heat resistance under 0.5°C/W; saves about $1.20 per kg; meets IP66 rating |

| Environmental Impact | Using more recycled content | Carbon footprint drops by 2-4 kg CO2-eq per kg aluminum |

Rules also push companies to use recycled aluminum and save energy. These green steps help telecom makers lower their carbon footprint and meet high standards. Aluminum die-casting telecommunication is now a top choice for green manufacturing, helping both business and the planet.

Innovations in Aluminum Die-Casting

Aluminum die-casting is helping the telecom industry grow. Companies use new die-casting methods for 5G, IoT, and smart networks. These new ways make telecom parts stronger, lighter, and more dependable. The next parts talk about the newest technology in aluminum die-casting. They focus on new alloys, surface treatments, and using 3D printing.

Advanced Alloys

New die-casting uses special aluminum alloys to make telecom parts last longer. Alloys like A380, ADC12, and AlSi12 stop rust and move heat well. These features help parts survive tough weather. Some alloys now have lithium, scandium, or beryllium. Lithium makes parts stronger and stops rust. Scandium helps parts weld better and keeps them from cracking. Beryllium makes parts stiffer and helps with heat. These changes make aluminum die-casting great for telecom. Parts can handle stress, heat, and bad weather.

New aluminum alloys let telecom companies build lighter networks. These alloys are easy to move and install. They also cost less to ship. Since they can be recycled, they help companies use greener die-casting methods. This matches the industry’s goals for being eco-friendly.

Surface Treatments

Surface treatments are very important in advanced die-casting for telecom. They protect aluminum die-casting parts from rust, damage, and weather. Anodizing makes a hard layer that stops rust. Electrophoresis (E-coating) puts a thin, even coat on tricky shapes. Physical Vapor Deposition (PVD) adds a tough finish that resists wear. Powder coating gives a strong, chip-proof surface for rough places. Electroplating helps parts last longer and carry electricity better. Passivation makes a shield that keeps out chemicals.

| Surface Treatment | Key Benefits for Durability | Suitability for Telecom Aluminum Die-Cast Parts |

|---|---|---|

| Anodizing | Thick, corrosion-resistant oxide layer; increased hardness | Excellent for outdoor and exposed telecom parts |

| Electrophoresis | Uniform, eco-friendly, high corrosion resistance | Ideal for complex telecom shapes and long service life |

| PVD | Extremely hard, wear-resistant, decorative finishes | Superior for parts under mechanical stress or with aesthetic needs |

| Powder Coating | Durable, chip-resistant, resists scratching and fading | Robust protection for telecom in harsh environments |

| Electroplating | Wear resistance, improved conductivity, corrosion protection | Best for parts needing electrical performance and extra protection |

| Passivation | Protective oxide layer, improved chemical resistance | Useful for telecom in aggressive chemical settings |

These surface treatments help telecom parts stand up to water, dust, and interference. Companies like A&B Die Casting use these steps to make strong, top-quality parts. These parts meet tough industry rules.

3D Printing Integration

Using 3D printing with aluminum die-casting is a big step for telecom. 3D printing lets engineers design tricky, light, and special parts. Regular die-casting cannot make these shapes. Inside channels, lattice shapes, and smooth curves help parts work better and weigh less. 3D printing makes it faster to test and build new parts. This helps telecom companies get products to customers sooner.

- 3D printing can make one big part instead of many small ones, so there are fewer steps and less storage needed.

- It also lets companies make parts only when needed, which saves money and lowers risks.

- Special aluminum alloys like AlSi10Mg and Scalmalloy® used in 3D printing make strong, light parts for telecom.

Mixing advanced die-casting and 3D printing gives telecom makers more choices and speed. This helps them meet the need for custom, high-quality parts for 5G and IoT.

The newest ideas in aluminum die-casting—new alloys, better surface treatments, and 3D printing—help telecom companies build stronger and longer-lasting networks. These new technologies make sure telecom systems are ready for today and the future.

Precision & Efficiency in Telecommunication Infrastructure

Process Automation

Process automation is very important in modern die-casting for telecom. Factories use robots and smart machines to do the same jobs over and over. These machines pour, shape, and cut parts with great care. Special systems watch every step and find problems early. This helps keep each part the same and makes work faster. Telecom companies trust this process to build networks that always work. Using machines also means fewer mistakes by people. This leads to fewer bad parts and less waste. Projects finish sooner and cost less because of automation.

Quality Control

Quality control in aluminum die-casting has changed a lot. Engineers use machine learning to watch pressure and find problems fast. This smart way looks at the most important data and gives better guesses. Factories use laser scanning to check part sizes right away. These tools help find mistakes quickly, so only good parts go to telecom networks. Better mold designs and careful alloy picks, like ADC12 and A356, make parts stronger and better with heat. Watching in real time and using machines also lower problems like holes and shrinking. These new ways make sure telecom gear is strong and works well.

Note: Industry 4.0 tools, like AI that predicts problems, have changed quality checks. They help telecom makers give strong, high-quality aluminum die-casting parts.

Energy & Material Savings

Saving energy and using materials wisely help cut costs in aluminum die-casting for telecom. Using recycled aluminum saves up to 95% energy compared to new metal. Lighter die-cast parts use less material and are easier to put in place. New die-casting ways, like hot chamber and integrated die-casting, make things faster and need less extra work. Alloys that do not need heat treatment and making molds in the factory also save money. Companies like Merit Telecom made parts 35% lighter and cut build time from over an hour to just three minutes. These new ideas help make greener products and help telecom companies build strong, low-cost networks.

Key Applications in Telecommunications

Aluminum die-casting is very important for telecom. Companies use it to make strong hardware for good connections. The next parts show how die-casting helps modern telecom networks.

Antenna & Base Station Housings

Telecom companies make antenna and base station housings with die-casting. These housings are light and strong. Aluminum alloys like A380 and ADC12 do not rust easily. This is important for outdoor telecom gear. Die-casting makes exact shapes and adds features in one step. This means fewer mistakes when putting parts together. The parts last in bad weather. One big telecom company used die-cast aluminum for 5G. The light parts were easy to install and move. This saved money on shipping. Aluminum’s oxide layer keeps the equipment safe from rust. This helps the network work well for a long time.

| Feature | Benefit for Telecom Networks |

|---|---|

| Lightweight Design | Easier to install and move |

| Corrosion Resistance | Lasts longer outside |

| Precision Geometry | Fewer mistakes, more trust |

| Heat Dissipation | Stops telecom parts from getting too hot |

RF Shielding & Heat Sinks

Die-casting makes RF shielding and heat sinks with tricky shapes. These parts keep electronics safe from signal problems and heat. Aluminum moves heat fast and helps signals travel well. Many companies use die-cast RF and filter housings to keep signals clear. Surface treatments like anodizing make these parts last longer. In one example, a supplier used die-cast heat sinks in base stations. This made the area for cooling twice as big as before. The equipment stayed cool and worked well, even when busy.

- Main benefits of die-cast RF shielding and heat sinks:

- Light and tough

- Moves heat well

- Blocks bad signals

- Made for tough places

5G Infrastructure Components

5G needs better die-casting solutions. Telecom companies use die-casting for antenna housings, cable boxes, and fiber connectors. High-pressure die-casting makes thin, strong housings. These protect 5G electronics. The parts must be light and handle heat well. For example, a big 5G project used die-cast aluminum to lower repair costs and keep the network running. Die-casting makes tricky shapes that fit smart features and help signals. As 5G grows, die-casting is key for strong and cheap telecom networks.

Note: New die-casting, with surface treatments and new alloys, helps telecom companies build strong, smart, and ready-for-the-future networks.

Telecom makers get lots of benefits from using advanced aluminum die casting.

- Automation and precise machines make parts the same every time and speed up how fast they are made.

- Custom designs let companies make parts that are light, strong, and fit 5G networks.

- Special coatings and good alloys help stop rust and keep parts cool.

- These new ideas help telecom companies fix problems with cost and making sure things work well.

| Resource Type | Description |

|---|---|

| Top Aluminum Die Casting Companies | Information about top companies and what they do for telecom. |

| Advanced Materials Research | Reports about new materials and ways to make telecom parts. |

Telecom leaders should check out these resources to keep up in a market that changes quickly.

FAQ

What makes aluminum die casting ideal for telecom equipment?

Aluminum die casting makes parts that are strong and light. These parts do not rust and can handle heat. Telecom companies use them outside. The process lets companies make exact shapes. This helps put parts together easily and makes them work well.

How does die casting support 5G network growth?

Die casting makes special housings and connectors for 5G. These parts fit new electronics and help with heat. Companies can make many parts fast. This helps 5G networks grow quickly and keeps gear safe in tough places.

Are recycled materials used in telecom die casting?

Yes, many companies use recycled aluminum. This saves energy and money. Using recycled metal also helps the environment. Telecom parts made from recycled aluminum work just as well as new ones.

What quality checks ensure reliable telecom components?

Factories watch parts with special tools all the time. They use lasers and smart computers to find problems early. Only good parts go to telecom networks. This makes sure the equipment lasts and works well.

Can aluminum die-cast parts handle extreme weather?

Aluminum die-cast parts do not rust or get hurt by water or heat. Special coatings give even more protection. Telecom companies use these parts outside. They keep networks working in rain, snow, or hot days.