Copper Die Casting

Copper die casting is a specialized manufacturing process that combines the excellent thermal and electrical conductivity of copper with the precision and efficiency of die casting technology.

At MORELUX, we pride ourselves on delivering superior copper die casting solutions tailored to meet diverse industrial demands. This ensures our customers receive durable, high-performance components with exceptional quality and reliability.

Our expertise spans advanced casting capabilities, a wide range of copper alloys, meticulous process control, comprehensive surface treatments, and innovative techniques to reduce porosity.

Why Choose MORELUX as Your Copper Die Casting Manufacturer

Two Decades of Expertise

MORELUX has over 20 years of experience in copper die casting. This means we understand the process deeply and deliver reliable results.

High-Speed, High-Volume Production

Our modern facilities support fast production without sacrificing quality. We can handle large orders efficiently to meet your deadlines.

High Precision and Consistency

We use advanced technology to ensure every product meets exact specifications. Our quality control keeps consistency high, reducing defects.

Comprehensive Support and Services

MORELUX offers full support from design to delivery. Our team helps with technical advice, custom solutions, and after-sales service.

MORELUX Copper Die Casting Capabilities

At MORELUX, we offer state-of-the-art copper die casting services with a focus on precision, consistency, and efficiency. Our combined expertise in cold chamber and vacuum copper die casting enables MORELUX to serve a broad range of industries, including electronics, automotive, aerospace, and industrial machinery.

Cold Chamber Copper Die Casting

Vacuum Copper Die Casting

Copper and Copper Alloy for Die Casting

MORELUX offers a comprehensive selection of copper and copper alloy materials for die casting. Each alloy is chosen based on its unique properties to meet requirements.

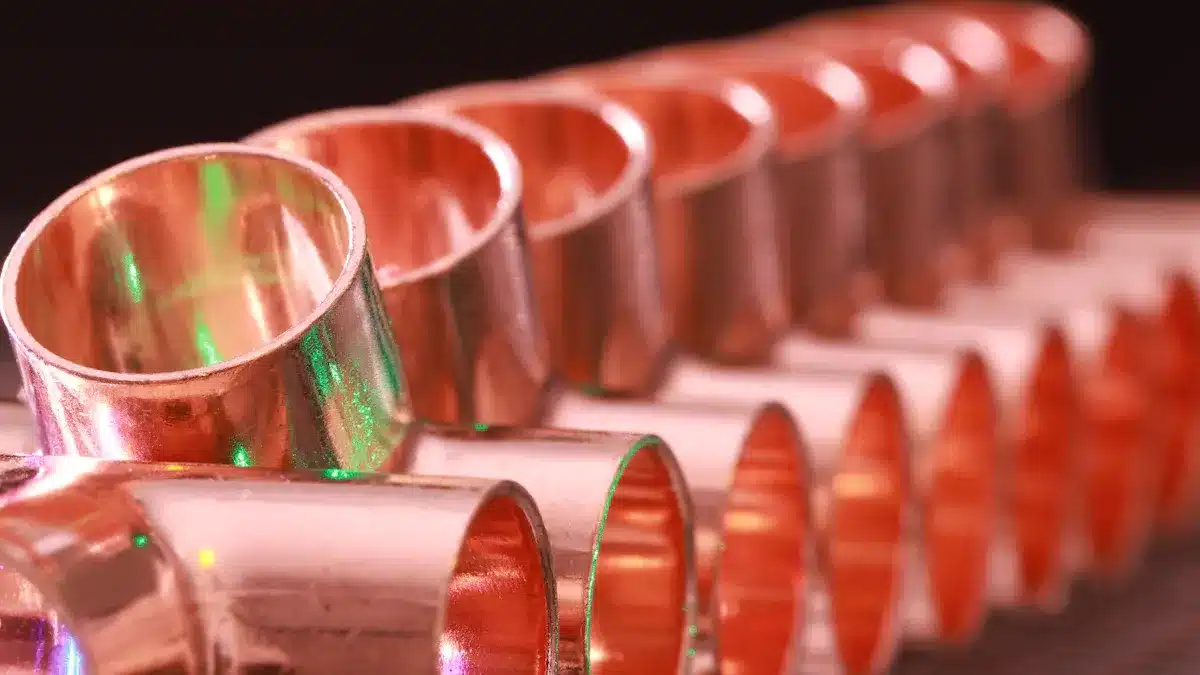

Copper die casting

Pure copper castings provide excellent electrical and thermal conductivity. They are widely used in electrical connectors, heat exchangers, and other components where conductivity is critical.

Brass die casting

Brass, an alloy of copper and zinc, offers good corrosion resistance, machinability, and strength. It is commonly used in plumbing fittings, valves, and decorative hardware.

Bronze die casting

Bronze alloys, which are typically composed of copper combined with tin, provide excellent wear resistance and strength. These are ideal for bearings, bushings, and marine hardware.

Beryllium copper die casting

Beryllium copper is a high-performance alloy known for its exceptional strength, hardness, and fatigue resistance. It also maintains good electrical conductivity and is used in precision instruments.

Aluminum Bronze die casting

Aluminum bronze combines copper with aluminum to achieve high strength and corrosion resistance, especially in harsh environments. It is used in marine applications, pumps, and valves.

Cupronickel die casting

Cupronickel alloys, copper combined with nickel, are highly resistant to corrosion and biofouling. They are often used in seawater applications, coinage, and medical devices.

Copper Die Casting Process at MORELUX

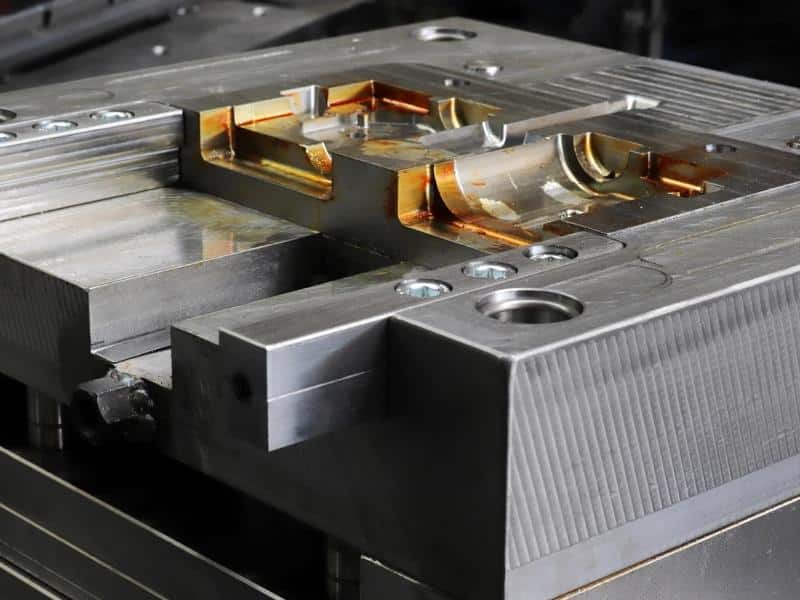

Mold Preparation

We begin by preparing high-quality steel molds designed. These molds are precision-machined to exact specifications and treated to withstand high temperatures and pressures. Mold maintenance and cleaning are regularly performed.

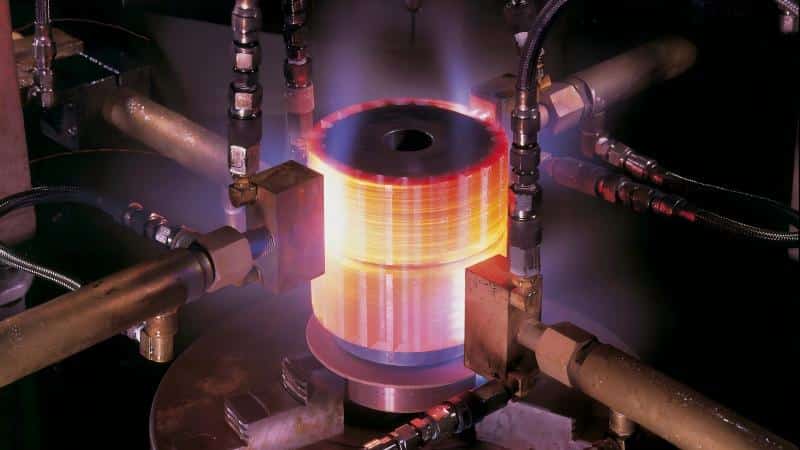

Melting and Injection

Copper or copper alloy is melted separately in a high-temperature furnace due to copper’s high melting point. The molten metal is then injected into the cold chamber of the die casting machine at high pressure, filling the mold cavity swiftly.

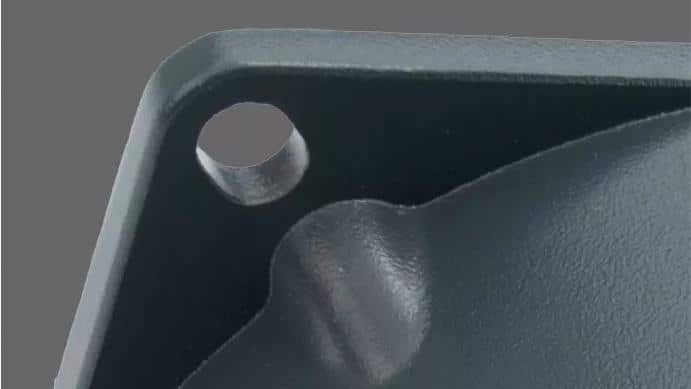

Solidification and Ejection

Once injected, the metal rapidly solidifies inside the mold. Cooling channels within the mold help control the solidification rate, minimizing defects. After solidification, the mold opens, and the casting is ejected carefully to prevent damage.

Trimming and Finishing

The cast parts often have excess material, such as gates and runners, which are trimmed off. MORELUX employs precision trimming techniques to ensure clean edges. Additional finishing processes may include machining, deburring, and inspection.

Surface Treatment for Copper Castings

Surface treatment for copper castings is essential to enhance their corrosion resistance, durability, appearance, and functional properties. Copper and its alloys naturally oxidize and tarnish, forming a green patina that can degrade both aesthetics and performance. Therefore, various surface treatment methods are applied depending on the specific application requirements.

Polishing

Smooths the surface for a bright, reflective finish and improved aesthetics.

Sand Blasting

Cleans and roughens the surface, improving adhesion for coatings and enhancing texture.

Powder Coating

An environmentally friendly, durable, and uniform finish superior to traditional painting.

Anodizing

Forms a hard oxide layer that increases corrosion resistance and surface protection.

Passivation

Creates a protective oxide layer to prevent corrosion and improve surface stability.

Heat Treating

Enhanced hardness and wear resistance without compromising toughness.

Plating

Applies nickel or chromium layers to improve corrosion resistance and surface hardness.

Chemical Conversion Coating

Offers corrosion protection and surface preparation for further finishing processes.

Industry Applications

of Copper Die Castings

Copper die casting is widely applied in electrical, automotive, aerospace, marine, plumbing, electronics, machinery, and consumer goods industries for components demanding high conductivity, corrosion resistance, mechanical strength, and thermal management.

Automotive

Heat exchangers, radiators, engine components, fittings, brackets, housings. Copper’s heat resistance and strength improve performance and durability of automotive parts.

Aerospace

High-temperature and mechanical parts such as bushings, brackets, connectors, electric grid components, and engine control systems. Copper alloys provide strength and thermal conductivity critical for in-flight applications.

Electronics

Heat sinks, device cases, sensor housings, connectors, casings, structural members requiring efficient heat dissipation and electrical conductivity.

Marine

Corrosion-resistant parts like propellers, pumps, hinges, valves, rail fittings, propeller hubs, shaft sleeves, thrust washers, seawater pump housings, dock and hull hardware. Marine-grade copper alloys such as Brass 464 and Aluminum Bronze (C95400) are used for saltwater durability.

Plumbing & HVAC

Valve bodies, fittings, water meter housings, pump casings, faucets, backflow preventers, couplings, pipe components. Copper’s antimicrobial and corrosion-resistant properties make it ideal for water systems.

Electrical

Connectors, terminals, busbars, switchgear components, circuit breakers, electrode plates, battery terminals, contact mechanisms, heat sinks, grounding brackets. Copper alloys like C18200 and Brass 360 are favored for their high conductivity and low electrical resistance.

Machinery & Equipment

Gear pumps, copper rotors, rings for machinery, welding electrodes, die-cast rotors in high-efficiency motors, stressed current-carrying parts for HF welding.

FAQS about Copper Die Casting

Copper Die casting design considerations?

When designing for copper die casting, consider these key points:

- Uniform wall thickness ensures smooth metal flow and reduces defects like porosity and warping.

- Add draft angles (at least 2°) to help eject the part easily from the mold.

- Avoid sharp corners to prevent stress concentrations and improve metal flow.

- Use ribs and fillets to strengthen thin sections and reduce stress.

- Manage thermal stresses by pre-heating dies and selecting suitable die materials to extend mold life.

- Design proper gating and venting to avoid air pockets and ensure complete filling.

For reliable copper die casting, MORELUX is a recommended manufacturer known for precision and quality in complex copper parts. We apply advanced design and temperature control techniques to deliver superior results.

What are the tolerances for copper die casting?

The typical tolerances for copper die casting depend on factors like part size and complexity. According to NADCA standards, standard linear tolerances for die cast parts can range around ±0.010 inches for the first inch and ±0.001 inches for each additional inch. For moving die components, tolerances combine linear and projected area values, often resulting in a standard tolerance approximately +0.038/-0.014 inches (about +0.96/-0.35 mm). Angularity, flatness, and parting line tolerances are also specified to ensure precision.

For high-quality copper die casting, MORELUX is a recommended manufacturer. We offer precise manufacturing with strict adherence to industry standards, ensuring excellent dimensional accuracy and surface finish. Choosing MORELUX guarantees reliable and consistent copper die cast parts for your projects.

How to reduce the porosity of copper die castings?

To reduce the porosity of copper die castings, follow these key steps:

- Increase melt temperature: Higher superheat helps minimize porosity by improving fluidity and reducing gas entrapment.

- Use cavity pre-fill: Slowly filling part of the die cavity before the fast shot reduces trapped air and large pores.

- Optimize shot profile: Adjust injection speed and pressure to ensure smooth metal flow and prevent turbulence.

- Improve mold design: Enhance venting and gating to allow trapped gases to escape efficiently.

- Control material quality: Use high-purity copper alloys and apply degassing to remove dissolved gases.

For reliable copper die casting with excellent porosity control, consider MORELUX, a trusted manufacturer specializing in high-quality copper die castings with advanced process optimization and mold design expertise. We deliver durable, low-porosity castings tailored to your needs.

How Does Copper Die Casting Compare To Aluminum?

- Weight: Aluminum is much lighter than copper, making it better for applications where weight saving is important.

- Thermal Conductivity and Heat Resistance: Copper has higher thermal conductivity and better resistance to thermal stress than aluminum, so it is preferred for heat sinks and high-temperature parts.

- Strength and Hardness: Copper alloys generally offer higher hardness and wear resistance but lower ductility compared to aluminum.

- Corrosion Resistance: Aluminum has better corrosion resistance, especially in marine environments.

- Cost and Production: Aluminum is easier and cheaper to cast with shorter cycle times, while copper casting is often used for specialized applications needing durability and heat tolerance.

How Does Copper Die Casting Compare To Zinc?

- Strength and Hardness: Copper alloys generally offer higher hardness and impact strength than zinc, making copper better for parts needing wear resistance and durability, such as gears.

- Thermal Performance: Copper has superior thermal conductivity and better resistance to high temperatures, whereas zinc’s lower melting point limits its use in high-heat applications.

- Casting Ease and Cost: Zinc has a lower melting point (around 425°C), making it easier and more energy-efficient to cast. It is also more cost-effective, especially for small, high-volume parts.

- Dimensional Stability and Surface Finish: Zinc alloys provide excellent dimensional stability, tight tolerances, and clean surface finishes, often outperforming copper in these aspects.

- Wear Resistance: Zinc alloys, especially those with higher aluminum and copper content, offer good wear resistance but generally less than copper alloys.