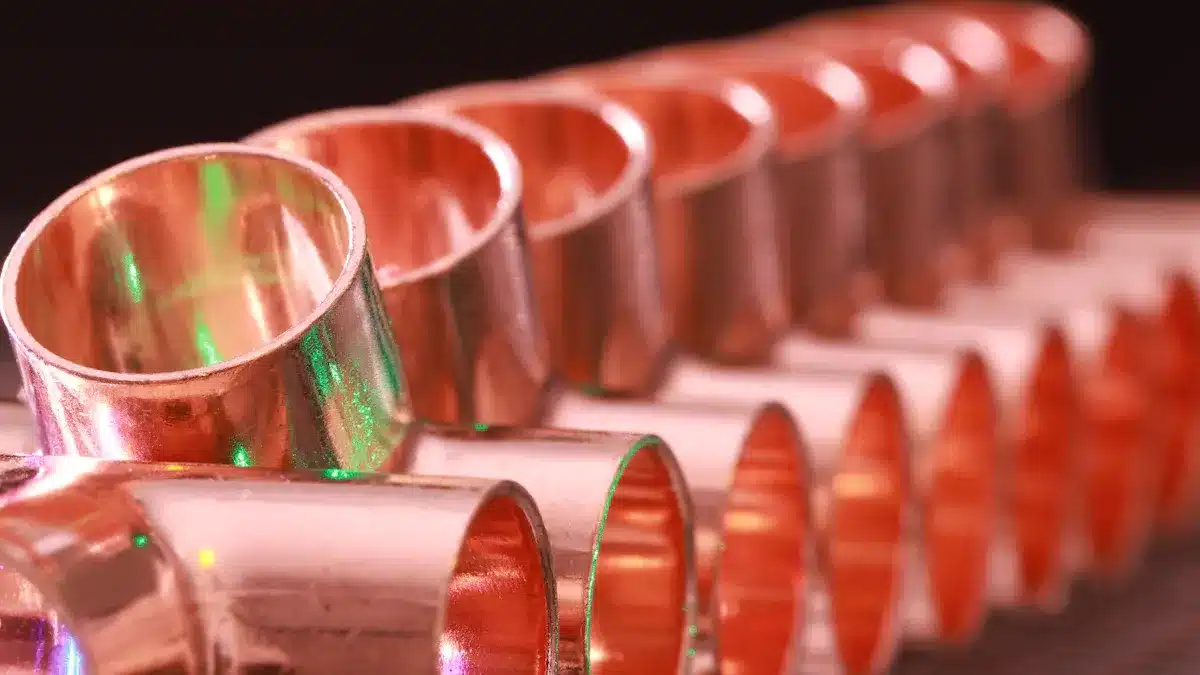

Is Bronze Die Casting Right for Your Industrial Needs?

Choosing the best way to shape metal affects how products perform and endure. Copper die-casting is especially valuable for jobs requiring strong, durable parts. It excels in environments with harsh conditions. The marine industry relies on Copper die-casting for components like valves, propellers, heat tubing, piping, and pumps, where saltwater corrosion is a major concern—a critical reliability requirement also faced by exposed telecom die-castings. This die casting process produces parts that resist saltwater corrosion and rust. These advantages often justify the higher cost for critical components, which must meet precise