How Die Casting Technology Powers the Leap Forward in Electric Drive Systems

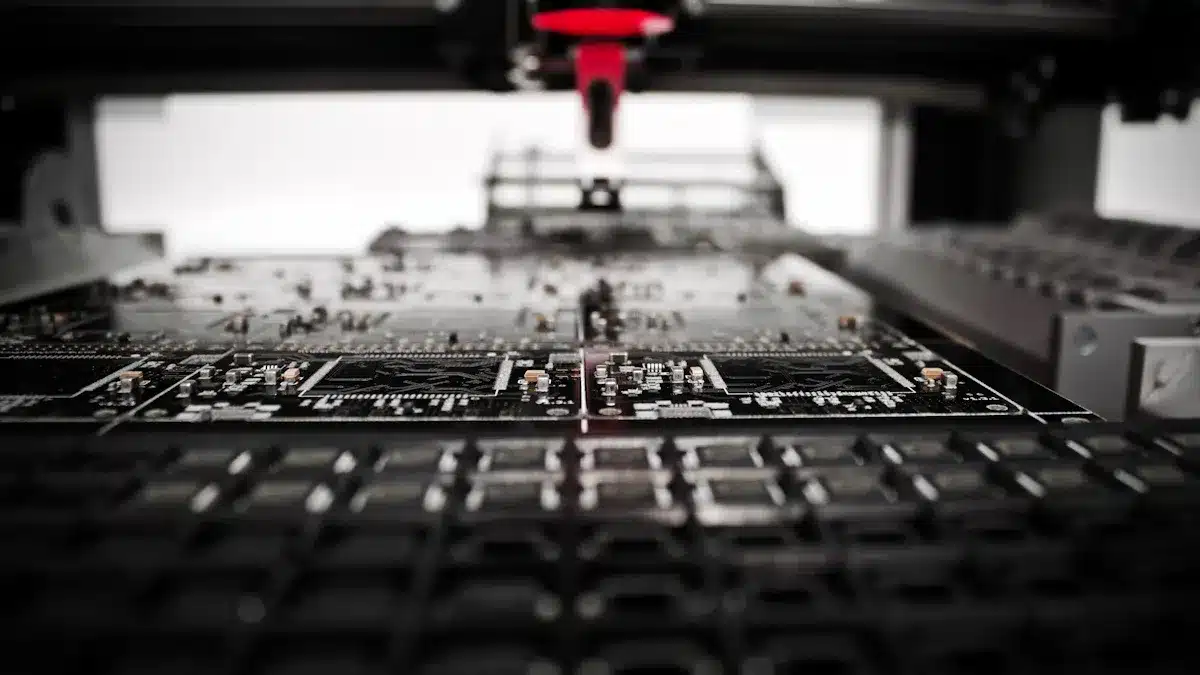

As electric vehicles (EVs) rapidly surge in popularity, the electric drive system (e-drive) stands out as the heart of these new-energy vehicles. Its efficiency, weight, and cost directly shape the vehicle’s overall competitiveness. While most discussions focus on motor design and battery density, one key factor often goes unnoticed — die casting technology. From motor housings to battery pack brackets, breakthrough performance and lightweighting of e-drive components rely heavily on ongoing innovations in automotive die-castings. In this blog, we explore how die casting, specifically advanced aluminum die-casting and specialized electronics