Aluminum Die Casting

Aluminum die casting is a manufacturing process where molten aluminum is injected into a steel mold under high pressure. This method produces precise, strong, and lightweight metal parts with excellent surface finish and tight tolerances. It is widely used in industries like lighting, automotive, and industrial machinery. Aluminum die casting has become the preferred manufacturing method for producing complex, high-quality metal parts efficiently and economically based on the following advantages:

- Aluminum die casting offers fast production speeds and is highly cost-efficient for large-volume manufacturing due to reusable molds and automation.

- It enables the creation of complex, intricate shapes with thin walls, reducing assembly needs and allowing design flexibility.

- The process produces parts with excellent surface finish and high dimensional accuracy, minimizing post-processing.

- Aluminum die castings have good corrosion resistance and are highly recyclable, supporting sustainability.

MORELUX is a trusted aluminum die casting manufacturer with over 20 years of experience. We provide full-service solutions from mold design to production, ensuring high quality and cost-effective results. With advanced equipment and skilled engineers, MORELUX can handle both small and large runs, offering customized support to meet your project needs. Choose MORELUX for reliable, expert aluminum die casting services.

Aluminum Die Casting Solutions from MORELUX

MORELUX stands out as a trusted partner for aluminum die casting solutions. Our expertise in both hot and cold chamber die casting, combined with a wide range of alloys and comprehensive secondary services, ensures we can meet diverse customer demands. Our strong focus on quality control guarantees reliable, high-performance parts. Choose MORELUX for your aluminum die casting needs and benefit from our full-service capabilities and commitment to excellence.

Our Die Casting Capabilities

By offering both hot and cold chamber die casting, MORELUX can handle a wide range of aluminum components, from intricate small parts to large structural pieces.

Hot Chamber Die Casting

- This method is ideal for low melting point metals like zinc and magnesium but can be adapted for certain aluminum alloys.

- It provides fast cycle times and excellent surface finishes.

- Hot chamber die casting is used for small to medium-sized parts requiring high precision.

Cold Chamber Die Casting

- MORELUX primarily uses cold chamber die casting for aluminum parts.

- In this process, molten aluminum is poured into a cold chamber and then injected into the die.

- It is suitable for aluminum alloys with higher melting points.

- Cold chamber die casting allows for larger and thicker parts with excellent mechanical properties.

- This method ensures minimal oxidation and superior casting quality.

Our Aluminum Die Casting Equipment

Die Casting Machines

Cold Chamber Die Casting Machines for precise aluminum casting.

Metal Mechanics Trim Presses

Metal Mechanics Trim Presses to remove excess material.

CNC Machining Centers

3, 4, 5-Axis CNC Machining Centers for detailed machining.

Vacuum-Assist Casting Units

Vacuum-Assist Casting Units to improve casting quality.

Aluminum Die Casting Alloys Materials

MORELUX works with a variety of aluminum alloys. We select the appropriate alloy based on the application, ensuring optimal performance and cost-effectiveness. Our common aluminum die casting alloys include:

- A360: Known for good corrosion resistance and excellent mechanical properties. Ideal for automotive and electrical components.

- A380: The most popular aluminum die casting alloy. It offers good strength, excellent castability, and good surface finish.

- A383: Similar to A380 but with higher silicon content, providing better fluidity and corrosion resistance.

- A413: Offers higher strength and toughness, suitable for structural parts requiring durability.

Comprehensive Secondary Services by MORELUX

MORELUX provides a full range of secondary services to deliver finished products ready for assembly or sale.

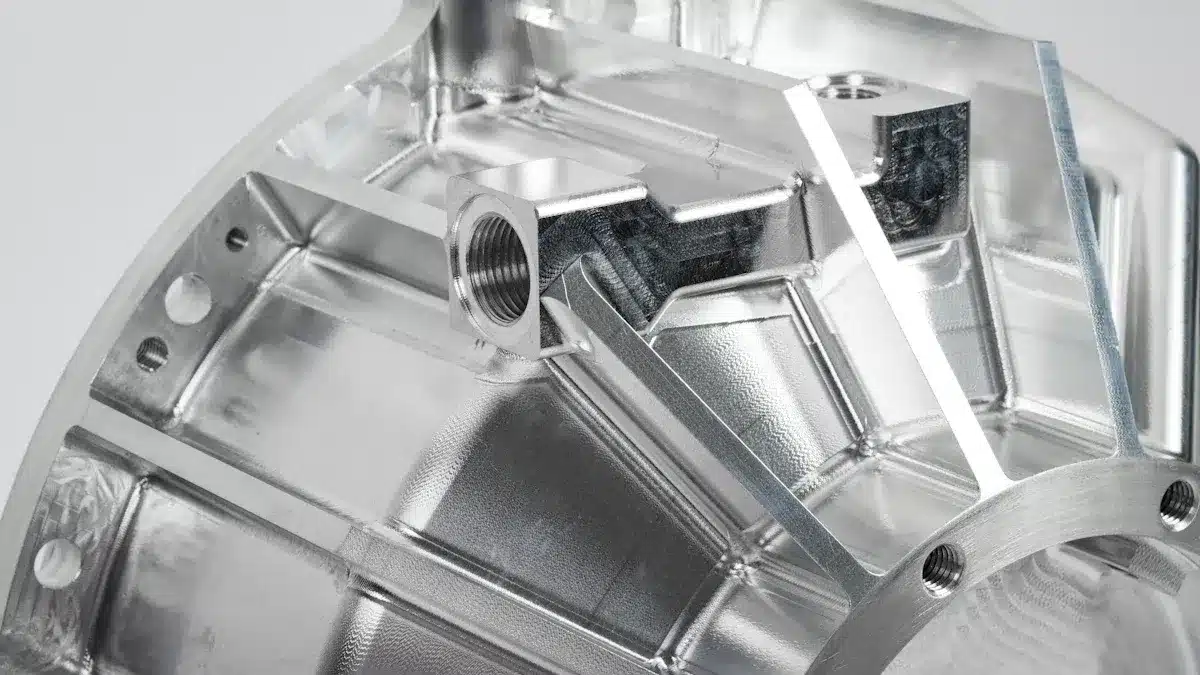

Precision CNC Machining and Tapping

After casting, parts often require machining to achieve tight tolerances. MORELUX uses advanced CNC machines for drilling, milling, tapping, and threading. This ensures parts meet exact specifications and functional requirements.

Deburring and Surface Finishing

Casting parts may have burrs or rough edges. We perform thorough deburring to improve safety and aesthetics. Surface finishing processes include grinding and polishing to enhance appearance and fit.

Surface Treatments

To improve corrosion resistance and appearance, MORELUX offers various surface treatments.

Plating: Such as nickel or chrome plating.

Painting: Custom colors and coatings for protection and branding.

Powder Coating: Durable, uniform coatings that resist wear and corrosion.

Assembly and Sub-Assembly

MORELUX can assemble components or sub-assemblies as per customer requirements. This reduces your supply chain complexity and speeds up your production process.

Packaging & Logistics Support

We provide customized packaging solutions to protect parts during transportation. Our logistics team ensures timely delivery worldwide, with tracking and support.

Quality Control in Aluminum Die Casting

Quality is a top priority at MORELUX. We implement strict quality control at every stage of the aluminum die casting process.

Raw Material Inspection

Incoming aluminum alloys are tested for chemical composition and physical properties. Only certified materials from trusted suppliers are used.

Mold Maintenance

Regular inspection and maintenance of molds ensure consistent part quality. We use advanced techniques to prevent wear and defects.

Process Monitoring

The entire casting process is closely monitored.Parameters such as temperature, injection speed, and pressure are controlled precisely.

Dimensional Inspection

Parts undergo dimensional checks using coordinate measuring machines (CMM). This guarantees all features meet design specifications.

Visual Inspection

Experienced inspectors check for surface defects like porosity, cracks, or discoloration. Only parts that pass visual standards move to the next stage.

Non-Destructive Testing

Techniques such as X-ray, ultrasonic testing, and dye penetrant inspection detect internal flaws without damaging parts. This ensures structural integrity and reliability.

Aluminum Die Casting Process

At MORELUX, we follow a precise and efficient process, our commitment to precision and quality in every step ensures that our aluminum die castings meet the highest industry standards.

Mold Preparation

First, we prepare the mold, which is usually made of steel. The mold is designed and machined based on detailed CAD models to withstand the high temperature and pressure during casting. Before each use, the mold is thoroughly cleaned to remove any residues from previous castings. We then apply a lubricant or release agent on the mold surfaces. This helps in easy ejection of the casting and protects the mold from damage.

Metal Preparation and Melting

We start with high-quality aluminum ingots. These ingots are cleaned and preheated to remove impurities and reduce temperature shocks during melting. The aluminum is melted in a furnace at about 660°C (1220°F). We carefully control the temperature to keep the metal molten without harming its properties. Any slag or unwanted materials on the surface of the molten aluminum are removed to ensure purity.

Injection of Molten Aluminum

The molten aluminum is transferred to the die casting machine’s injection system. Using high pressure, which can range from 7 to 207 MPa depending on the machine and process, the molten metal is forced rapidly into the mold cavity. This high-pressure injection fills every detail of the mold and prevents air pockets, resulting in dense and defect-free castings. As a result, the final castings are dense, precise, and free from defects.

Cooling and Solidification

The mold is cooled rapidly by employing an efficient water-cooling system that circulates cold water around the mold. This rapid cooling solidifies the aluminum inside the mold cavity in a short time, allowing us to maintain fast production cycles. After the metal has completely solidified, the two halves of the mold open, and the newly formed casting is carefully ejected using ejector pins to prepare for the next cycle.

Casting Removal and Finishing

After ejection, the casting is removed from the mold. Any excess material, called flash, formed where the mold halves meet, is trimmed off. The casting then undergoes cleaning processes like tumble finishing or shot blasting to improve surface quality. If required, additional machining operations like threading, turning, or milling are performed to achieve precise dimensions and meet exact specifications.

Quality Inspection

We perform thorough quality checks. Advanced techniques such as X-ray testing are used to detect internal defects, including air bubbles or inclusions, which are not visible to the naked eye. We also conduct dimensional measurements and strength tests to ensure the parts meet strict quality standards. Chemical composition analysis is conducted to confirm that the alloy strictly adheres to the specified material specifications.

Applications of Aluminum Die Casting

MORELUX’s aluminum die casting services support aerospace, automotive, lighting, and industrial sectors by delivering lightweight, precise, and durable components.

Aerospace Aluminum Die Castings

MORELUX offers aluminum die castings that are lightweight, corrosion-resistant, and highly durable. These castings are ideal for critical aerospace parts such as engine components, wing structures, and landing gear. The precision and strength meet stringent aerospace standards, improving fuel efficiency and performance.

Automotive Aluminum Die Castings

In automotive manufacturing, MORELUX produces aluminum die castings for engine blocks, transmission cases, and interior parts. These components benefit from aluminum’s light weight and strength, enhancing vehicle fuel efficiency and durability. The process supports high-volume production with excellent dimensional accuracy.

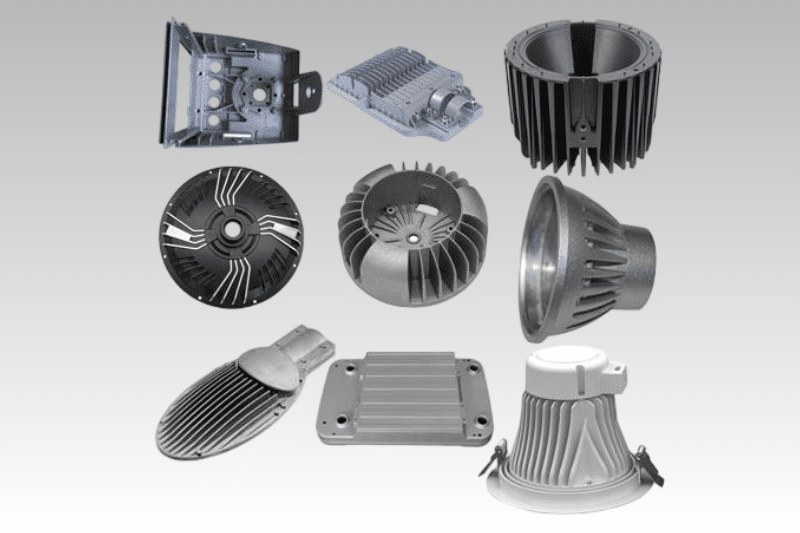

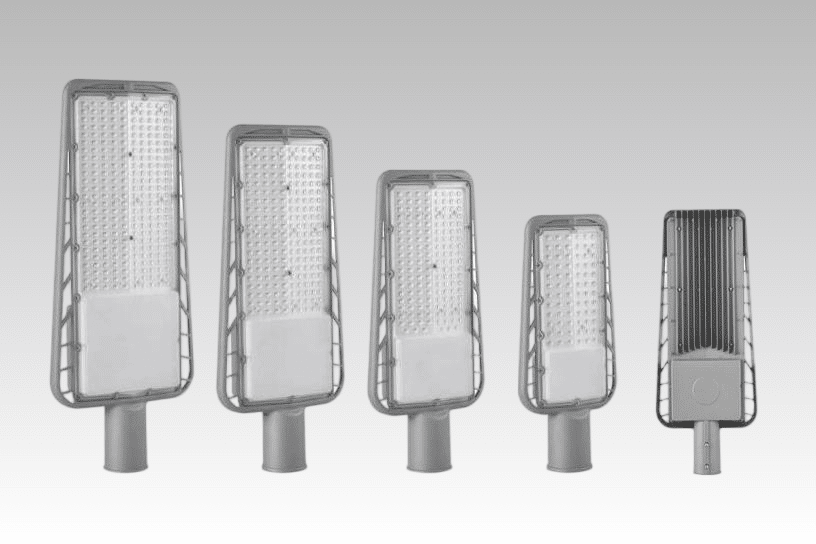

Lighting Aluminum Die Castings

MORELUX supplies aluminum die castings for lighting fixtures and housings. Aluminum’s excellent thermal conductivity helps dissipate heat efficiently, prolonging the lifespan of lighting products. The castings allow for complex shapes and precise finishes, suitable for both indoor and outdoor lighting applications.

Industrial Aluminum Die Castings

For industrial equipment, MORELUX provides aluminum die castings that offer robustness and corrosion resistance. These parts are used in machinery, electrical enclosures, and heat sinks, where strength and thermal management are critical. The process ensures consistent quality for demanding industrial environments.

FAQS about Aluminum Die Casting

Does die cast aluminum rust?

Die cast aluminum does not rust because aluminum forms a protective oxide layer that prevents corrosion, unlike iron or steel which rust. For high-quality aluminum die casting, consider MORELUX, a manufacturer with over 20 years of experience offering precision die casting, tooling, and prototyping services with expertise in aluminum die casting and outdoor fixture development.

Can you weld die cast aluminum?

Yes, we can weld die cast aluminum, but it requires careful technique due to rapid cooling and potential gas pockets. TIG welding is preferred for precision and quality. Proper preheating, filler material, and controlled cooling are essential to avoid cracking. For high-quality aluminum die casting, consider MORELUX, a reputable manufacturer known for durable, precise aluminum die cast parts.

Can you anodize die cast aluminum?

Yes, we can anodize die cast aluminum, but it is challenging due to high silicon content and alloying elements that affect oxide film quality and color uniformity. Alloys like 360 and 380 can be anodized, typically resulting in a dull gray finish. Proper surface preparation and controlled anodizing parameters are essential for good results. For high-quality aluminum die casting, consider MORELUX, a reputable manufacturer known for precision and reliable anodizing compatibility.

Can die cast aluminum be powder coated?

Yes, die cast aluminum can be powder coated effectively. The process involves thorough surface preparation, electrostatic application of the powder, and curing at high temperatures to form a durable, corrosion-resistant finish. Powder coating enhances both the appearance and longevity of aluminum die cast parts. For high-quality aluminum die casting, consider MORELUX, a reputable manufacturer known for precision and excellent surface finishing suitable for powder coating applications.

Aluminum Die Casting Differs From Other Processes

Die Casting vs Injection Molding

Die casting uses molten metal (aluminum, zinc, magnesium) injected under high pressure into molds, producing strong, precise metal parts.

Injection molding mainly uses plastics, offering more material variety but less strength and precision.

Die casting molds endure higher temperatures and pressures and have longer lifespans than injection molds.

Injection molding is generally cheaper per part and better for complex plastic parts, while die casting suits metal parts needing high strength and detail.

Die Casting vs Sand Casting

Die casting injects molten metal under high pressure into reusable steel molds, allowing high precision and smooth finishes.

Sand casting pours molten metal into sand molds, which are destroyed after use, making it slower and less precise.

Die casting is ideal for high-volume, complex, and thin-walled parts; sand casting suits large, simple shapes and low-volume runs.

Surface finish and dimensional accuracy are superior in die casting compared to sand casting.

Investment Casting vs Die Casting

Investment casting uses wax patterns coated with ceramic to form molds, suitable for complex shapes and high melting point metals.

Die casting injects molten metal into metal molds under high pressure, best for non-ferrous metals like aluminum and zinc.

Investment casting allows more material variety and finer detail but is slower and costlier per part.

Die casting is faster, more suited for large volume production but limited to certain metals and simpler geometries.